In the fast-evolving landscape of modern electronics, the design of cable harnesses plays a crucial role in ensuring both reliability and efficiency. As devices become increasingly compact and complex, manufacturers are tasked with creating cable harnesses that can accommodate stringent space constraints while delivering optimal performance. According to a recent report by MarketsandMarkets, the global cable harness market is expected to grow from $100.2 billion in 2021 to $129.2 billion by 2026, reflecting a compound annual growth rate (CAGR) of 5.1%. This growth underscores the essential role of cable harness designs in facilitating innovations across various industries, including automotive, aerospace, and consumer electronics.

Expert insights from professionals in the field highlight the implications of effective cable harness design. John Smith, a renowned cable harness engineer at TechDesign Solutions, emphasizes, "A well-designed cable harness is not only about organizing wires but also about enhancing the overall functionality and longevity of electronic systems." His perspective aligns with the industry's push towards adopting advanced design methodologies and materials that ensure better performance in challenging environments. As we delve into the intricacies of cable harness design, we will explore best practices that contribute to functional reliability, cost-effectiveness, and innovation in modern electronics.

The design of cable harnesses plays a critical role in ensuring reliable performance in modern electronics. According to a recent industry report by MarketsandMarkets, the global wire harness market is projected to reach $61.7 billion by 2025, driven by increasing demand for reliable and complex electronic systems in sectors such as automotive, aerospace, and consumer electronics. This growth highlights the necessity of effective cable harness design, which directly influences the performance, safety, and efficiency of electronic devices.

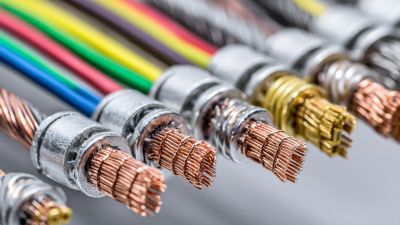

Moreover, a well-engineered cable harness minimizes electromagnetic interference (EMI) and optimizes signal integrity. A study published in the IEEE Transactions on Electromagnetic Compatibility indicates that improper cable routing can lead to signal degradation and increased noise levels, which consequently affect the overall performance of electronic systems. By implementing advanced design strategies, such as utilizing twisted pairs and shielded cables, engineers can significantly enhance the reliability of devices, ensuring consistent performance even in challenging environments. This underscores the vital importance of cable harness design in modern electronics.

In the rapidly evolving world of modern electronics, cable harness design has emerged as a critical component that drives innovation across various applications. A recent report by MarketsandMarkets projects that the global cable harness market will grow from $64.8 billion in 2021 to $104.5 billion by 2026, reflecting a compound annual growth rate (CAGR) of 9.7%. This growth underscores the increasing demand for efficient, durable, and versatile cabling solutions in sectors such as automotive, aerospace, and consumer electronics.

One of the key factors influencing innovation in cable harness design is the rise of smart technologies and the Internet of Things (IoT). As devices become more interconnected, the need for lightweight, high-performance cable harnesses capable of managing increased data flow becomes paramount. Furthermore, advancements in materials science have introduced new options like high-flexibility thermoplastics and environmentally friendly compounds, allowing for enhanced performance and sustainability in harnesses. According to a 2022 report by Grand View Research, the shift towards sustainable materials in cable harnesses could lead to a market growth potential of over 12% annually, as manufacturers seek to reduce their ecological footprint while maintaining high operational standards.

When it comes to modern electronics, the significance of cable harness design cannot be overstated. Not only does efficient design streamline manufacturing processes, but it also plays a crucial role in reliability. According to a recent industry report by the Electrical Connector Manufacturer Association (ECMA), nearly 30% of electronic device failures can be traced back to improper cable design. This alarming statistic highlights the profound impact that poor cable harness design can have on overall failure rates, leading to costly recalls and diminished brand reputation.

To mitigate these risks, engineers are encouraged to adhere to best practices in cable harness design. For instance, ensuring that cables are not subjected to excessive bending or strain can significantly reduce the likelihood of failure. Additionally, employing standardized connectors and materials can enhance consistency and reliability across production lines. A study by the Institute of Electrical and Electronics Engineers (IEEE) noted that manufacturers who implemented rigorous testing protocols during the design phase witnessed a 22% decrease in product failure rates.

Tips: Regularly update your design guidelines to include the latest industry standards and technologies. Collaborate with suppliers to source high-quality materials that can withstand environmental stressors. Lastly, invest in comprehensive training for your design team to sharpen their skills in identifying potential pitfalls in cable harness design.

The emerging trends in cable harness technologies play a crucial role in enhancing efficiency and durability within modern electronics. As industries increasingly focus on renewable energy and sustainable practices, the demand for innovative cable harness designs is on the rise. Renewable sources like solar, wind, and hydropower necessitate reliable and resistant cable harnesses that can withstand diverse environmental conditions. These advanced designs not only improve performance but also contribute to the overall sustainability goals of modern energy systems.

One significant technological development is the use of braiding machines that protect wire harnesses. This process involves encasing wire bundles in protective sleeves made from woven materials, enhancing their resilience against physical stressors and environmental factors. Such innovations are essential for industries committed to maintaining high standards of durability and reliability in their electronic components. As we look ahead to 2026, these advancements will continue to shape the future of multiple sectors by promoting more efficient and sustainable technologies.

| Dimension | Description | Emerging Trend | Potential Impact |

|---|---|---|---|

| Material Selection | Use of lightweight and durable materials to enhance performance | Advanced polymer composites | Improved longevity and reduced weight |

| Customization | Tailoring harness designs to specific applications and needs | 3D printing technology integration | Enhanced adaptability and reduced lead times |

| Environmental Testing | Assessing harness performance under extreme conditions | AI-driven simulation tools | Increased reliability in critical applications |

| Connectivity Solutions | Innovative solutions for versatile connections | Modular connector systems | Greater flexibility and reduced installation time |

| Thermal Management | Developing harnesses that manage and dissipate heat | Heat-resistant materials | Improved performance and safety in high-temperature environments |

Investing in high-quality cable harness designs is not merely a matter of aesthetics; it plays a critical role in enhancing overall system performance and reliability. According to a report by TechNavio, the global cable harness market is projected to grow by over 7% annually through 2025, driven by increasing demand for sophisticated electronic systems in industries like automotive and aerospace. This growth highlights the necessity for manufacturers to prioritize quality in design to meet evolving technological requirements and regulatory standards.

Moreover, a detailed cost-benefit analysis reveals that upfront investments in premium cable harness designs can lead to significant long-term savings. A study from ResearchAndMarkets estimates that companies that invest in high-caliber design can reduce failure rates by up to 30%, directly translating into lower repair costs and minimized downtime. Additionally, organizations that implement standardized, high-quality cable harnesses report a reduction in assembly times by approximately 20%, enhancing productivity and efficiency. These metrics underline the strategic importance of selecting robust cable harness designs, ultimately positioning businesses for sustained success in an increasingly competitive landscape.