A tour of Multi-Tek's cable assembly manufacturing facility

When our customers walk into our manufacturing facility, they notice a few things immediately — it’s clean, it’s bright and it’s organized. And it’s no accident.

We like showing people around. So if you’re in the Portland, OR, area, get in touch with us and stop by. If you’re elsewhere, here’s a look at what goes on inside our 20,000-square-foot facility.

Trusted by

Expert support from design to delivery

Minimum orders starting at 100 pieces

99.8% on-time delivery

Every tour starts at receiving

When our team receives parts for production, they immediately log them into our inventory management system. Our proprietary tech — we call it CableTracker — lets us keep track of all orders and their requirements in real-time, so the rest of our staff are set up for success down the line.

Our inventory team shrinks lead times with a smart kitting program

At inventory, we kit parts based on the production needs of the entire facility. We lean on our AI-based technology to find out exactly what work we can do with the parts we already have.

If one component is late to arrive at our facility, we can have the project prepped for quick completion as soon as the part comes in.

Cut-strip-terminate machines test quality during volume manufacturing

State-of-the-art CST machines automatically run tests on every crimp they produce to check for reliability – a crimp with big errors goes straight in the trash.

These stations are also staffed with experienced operators who visually inspect for subtle errors that machines can’t catch. We take care with this step because crimp failures are difficult to spot and costly to ignore.

Wire processing accommodates all cable types

Every order has different requirements, and when our CST machines aren’t the right fit for the job, we have everything we need to craft the right cable assemblies. We invest in our equipment to make the best possible crimps and to strip wire as efficiently as possible.

But if hand crimping is necessary, we have the right people to do that too. Our equipment and personnel give us the flexibility we need to meet any order.

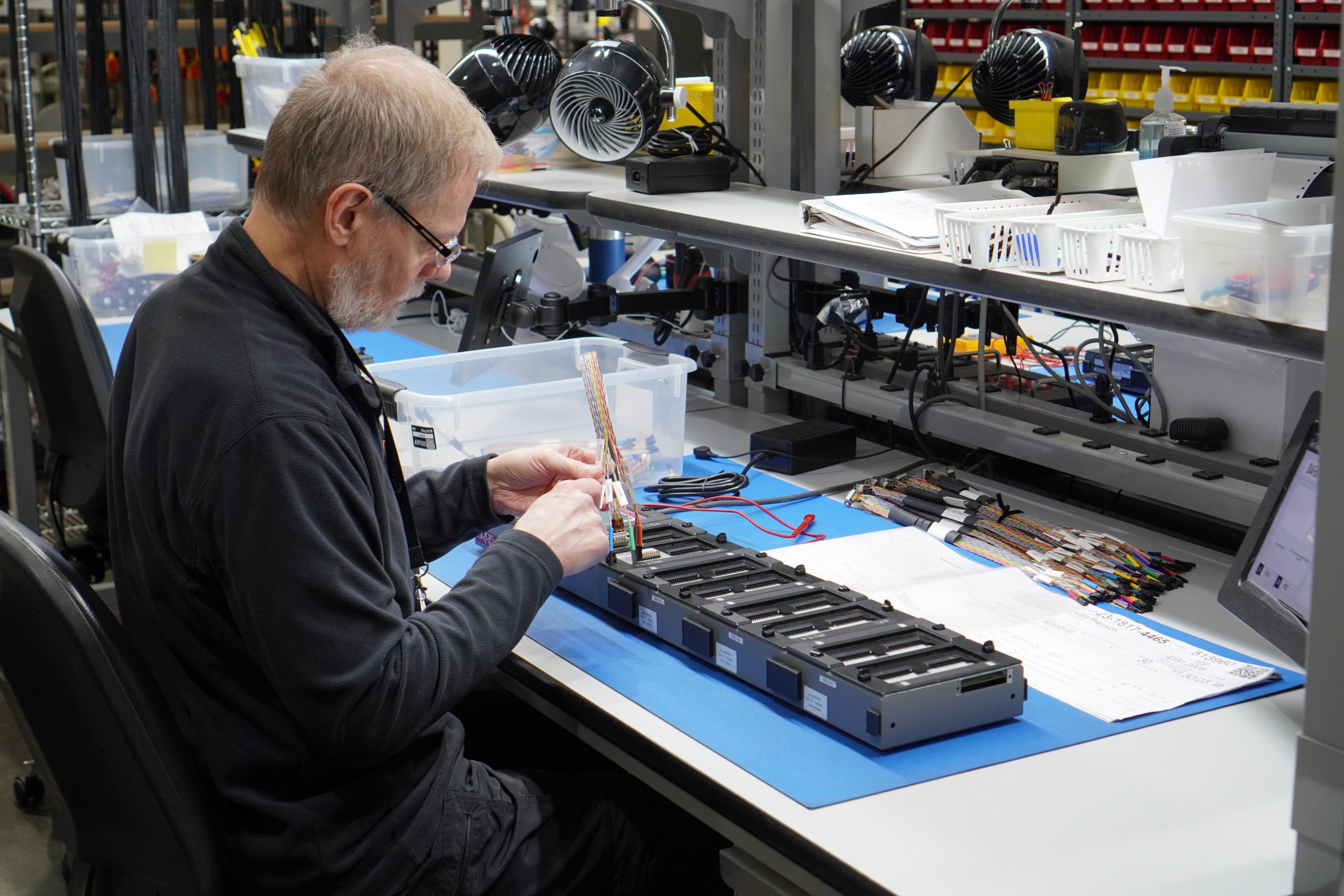

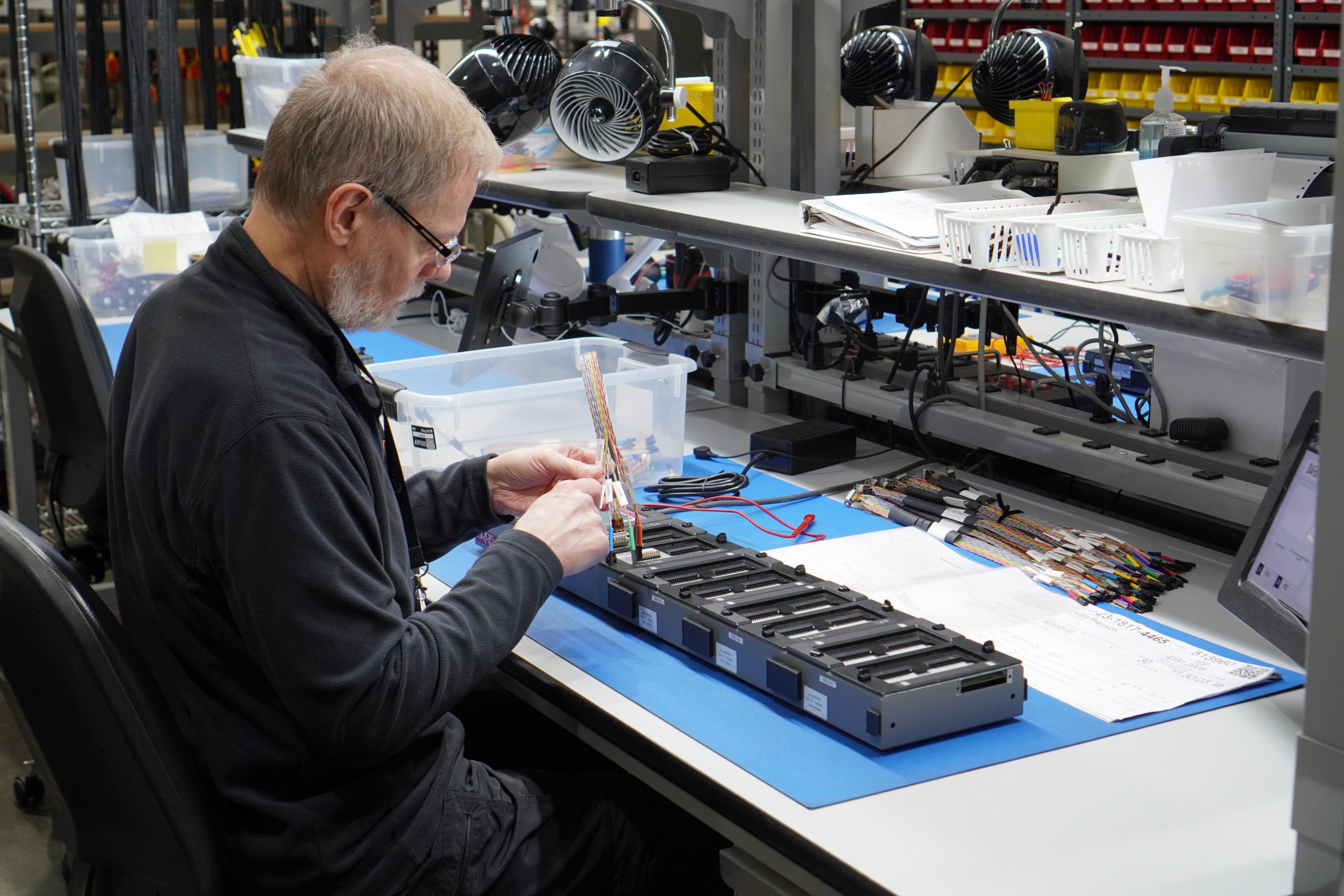

Visual diagramming leads to error-free assembly

Good cable assembly means consistency. And by providing all of our assembly stations with monitors that guide employees on construction best practices for each cable, we minimize any differences between cables — another way reliability is built into every step of our process.

Proprietary tech augments dependable testing

Computerized testing on Cirris equipment is par for the course when it comes to cable assembly. But CableTracker goes a step further, confirming customer-specific pass/fail requirements at the point of testing and representing last-minute design changes accurately for perfect version control.

QC stays in communication with the whole team

At Multi-Tek, we stake our reputation on our quality control. That’s why our QC team is always kept updated through CableTracker on any possible concerns that customers or our internal team might have on an order.

That means QC doesn’t need to rely on informal, institutional knowledge to know what our customers need. They double-check every feature of every cable we build, so you never have to.

Shipping meets a wide variety of customer preferences

No matter what shipping requirements you have, we’re able to accommodate them. Just like the rest of our facility, the team here has immediate access to order updates via CableTracker.

That means last-minute changes to delivery locations are made simple. We make sure we get your cable assemblies over to you on time and without a hitch.

How we'll earn your trust

Reasonable minimum order quantities

In special cases, we can build as few as 10 cables per order.

On-demand engineering

From next-gen improvements to new design finalization, our expertise is all yours.

Robust quality control systems

QC engineers go beyond sample testing to produce 100% functionality.

ISO, UL and IPC certified

Our cables are IPC/WHMA-A-620 Class 2 certified by default, or Class 3 when requested.

Responsive support and communication

Expect a detailed quote in three days or less.