In the realm of modern engineering and manufacturing, the importance of electrical harness assembly cannot be overstated. This critical process involves the systematic organization and integration of wires and components into a cohesive structure, ensuring that electrical systems function optimally. As projects become increasingly complex, the role of electrical harness assembly emerges as a cornerstone of efficiency, directly impacting the overall performance and reliability of the final product.

An effective electrical harness assembly minimizes the risks of electrical faults, reduces installation time, and enhances the scalability of designs. By streamlining the wiring process and facilitating easier maintenance, it paves the way for smoother project execution and better resource management. As industries continue to innovate and adapt to new technologies, recognizing the significance of electrical harness assembly will be essential for achieving successful outcomes and maintaining competitive advantage.

Ultimately, as projects demand greater precision and efficiency, focusing on the quality and execution of electrical harness assembly is imperative. Understanding its benefits enables teams to enhance productivity and integrate electrical systems seamlessly, propelling projects toward success in an increasingly demanding landscape.

Electrical harness assembly plays a pivotal role in enhancing project efficiency across various industries. A well-assembled electrical harness significantly reduces the installation time and minimizes potential errors during the integration stages of a project. According to a report by the International Society of Automation, projects that utilize optimized electrical harnesses can achieve a 20% reduction in assembly time, translating to substantial cost savings and improved productivity. This efficient wiring configuration allows for easier diagnostics and maintenance, ensuring that any issues can be swiftly identified and resolved, further contributing to the overall efficiency of operations.

Additionally, properly designed electrical harnesses can improve the safety and reliability of electrical systems. According to the IEEE Standards Association, well-organized wiring reduces the risk of electrical faults, which can lead to operational downtime and costly repairs. The integration of quality control measures in harness assembly not only ensures compliance with industry safety standards but also enhances the performance of the entire project. A study conducted by the National Electrical Manufacturers Association indicates that projects employing effective electrical harness solutions experience up to a 30% decrease in electrical failure rates, which ultimately leads to enhanced efficiency and project delivery timeliness.

Electrical harness assemblies play a crucial role in ensuring the efficiency of numerous projects across various industries. These assemblies consist of a set of cables or wires bundled together within a protective covering, designed to transmit electrical power or signals to different components of a system. Understanding the key components of electrical harness assembly can significantly enhance project planning and execution.

One of the primary components of an electrical harness assembly is the wire or cable, which is selected based on its conductivity, insulation type, and gauge to meet specific load requirements. Connectors are equally important, as they facilitate the secure joining of different wires and components, ensuring reliable electrical connections. Additionally, protective coverings, such as heat shrink tubing and conduit, safeguard the wire assembly from environmental hazards and mechanical wear, enhancing durability and longevity.

Furthermore, the organization and arrangement of the harness play a vital role in efficiency. Proper routing minimizes clutter and the risk of interference, while strain relief features help prevent damage at connection points. By meticulously designing each aspect of the electrical harness assembly, projects can achieve higher operational efficiency, reduced downtime, and enhanced performance, showcasing the undeniable importance of this component in modern electrical systems.

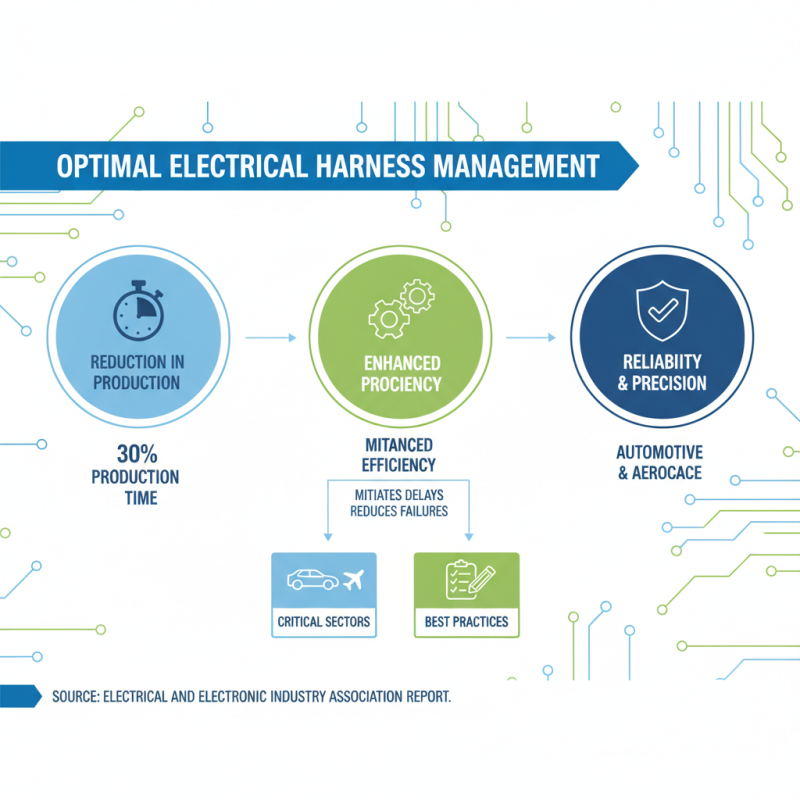

Optimized electrical harness design plays a critical role in enhancing project efficiency across various industries, particularly in automotive, aerospace, and industrial automation. According to recent industry reports, studies show that streamlined harness assembly processes can improve production timelines by up to 30%. This significant time reduction is primarily attributed to well-structured design layouts that minimize errors during assembly and installation, ultimately leading to faster project completion.

Moreover, an optimized electrical harness not only reduces assembly time but also enhances the overall reliability of electrical systems. Reports indicate that well-designed harnesses can decrease the likelihood of electrical failures by approximately 25%, a crucial factor in industries where safety and operational reliability are paramount. Furthermore, energy efficiency gains from optimized designs can lead to cost savings; for instance, reducing wire lengths and selecting appropriate materials can lower material costs by 15%, facilitating a higher return on investment for projects. By prioritizing advanced design techniques, companies can ensure their projects are not only completed on time but also meet stringent performance standards, thus driving long-term success.

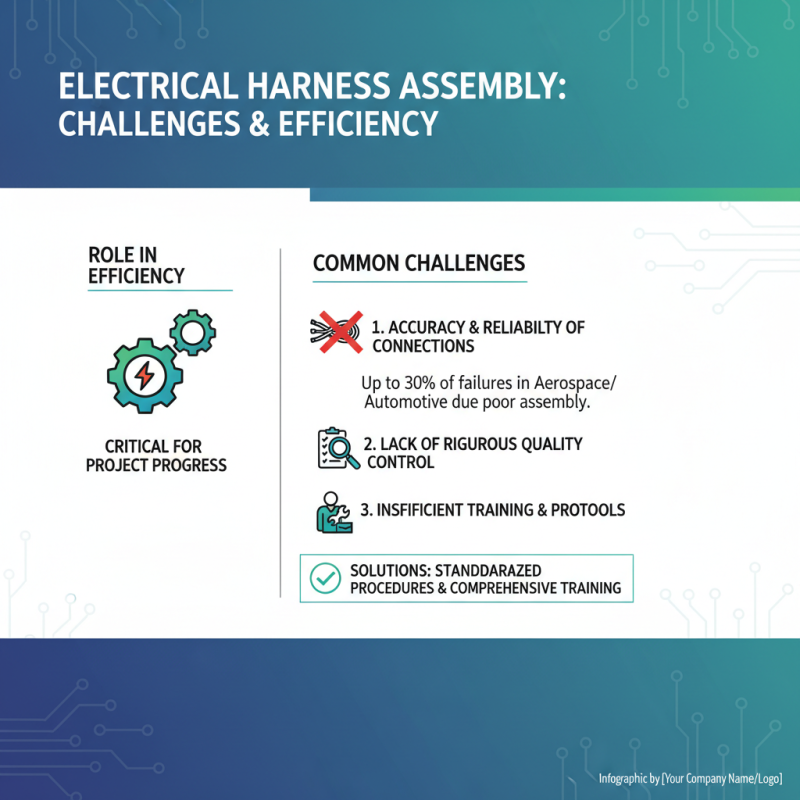

Electrical harness assembly plays a critical role in enhancing project efficiency, but it also comes with several common challenges that can impede progress. One significant challenge is ensuring the accuracy and reliability of connections within the harness. According to industry reports, up to 30% of electrical failures in aerospace and automotive sectors can be traced back to poor harness assembly practices. This highlights the necessity for rigorous quality control measures throughout the assembly process. Proper training and standardized protocols are essential to minimize errors and enhance overall performance.

Another challenge is managing the complexity of modern electrical systems. As industries move towards greater automation and connectivity, harness designs become increasingly intricate. This complexity can lead to difficulties in installation and maintenance, potentially causing delays in project timelines. A report from the International Wire and Cable Association indicates that simplifying harness designs can reduce assembly time by up to 25%. Implementing design-for-manufacturability principles can streamline production and improve efficiency.

Tips: To mitigate these challenges, investing in specialized training for assembly personnel can significantly impact productivity and quality. Additionally, utilizing simulation tools during the design phase allows for the identification of potential issues before physical assembly, saving valuable time and resources. Regularly reviewing assembly processes and incorporating feedback from the field can lead to continuous improvements in harness assembly efficiency.

Effective management of electrical harness assemblies is pivotal for enhancing project efficiency across various industries. According to a recent report by the Electrical and Electronic Industry Association, poor harness management can result in up to a 30% increase in production time. Implementing best practices in electrical harness management not only mitigates delays but also reduces the risk of potential failures. This is particularly crucial in sectors such as automotive and aerospace, where precision and reliability are paramount.

One key practice in electrical harness management is meticulous planning and documentation. Having a well-documented assembly plan allows for better communication among team members and ensures that all components are compatible. Industry studies show that companies that invest in comprehensive documentation and planning reduce assembly errors by as much as 50%. Additionally, adopting standardized harness designs can lead to quicker setups and streamline the training process for new employees, contributing to a more efficient workflow and cost savings in the long run. By emphasizing these best practices, organizations can enhance their operational efficiencies and achieve better project outcomes.