In recent years, the cable fabrication industry has experienced significant innovations, driven by the rising demand for high-performance and efficient connectivity solutions in modern technology. According to a report by MarketsandMarkets, the global cable manufacturing market is projected to reach $164.2 billion by 2026, growing at a CAGR of 6.4%. As industries such as telecommunications, automotive, and aerospace increasingly rely on sophisticated electronic systems, advancements in materials and manufacturing techniques for cable fabrication are vital.

Innovations such as the introduction of smart cables and enhanced insulation materials not only improve performance but also contribute to sustainability efforts by reducing waste and energy consumption. Therefore, understanding these advancements in cable fabrication is essential for industry stakeholders seeking to adapt and thrive in this rapidly evolving technological landscape.

Innovations such as the introduction of smart cables and enhanced insulation materials not only improve performance but also contribute to sustainability efforts by reducing waste and energy consumption. Therefore, understanding these advancements in cable fabrication is essential for industry stakeholders seeking to adapt and thrive in this rapidly evolving technological landscape.

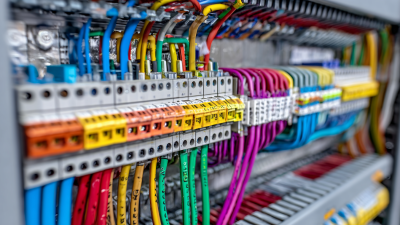

The evolution of cable fabrication techniques in the tech industry has undergone significant transformations in recent years, driven by the rapid advancements in technology and the increasing demand for high-performance connectivity solutions. Traditionally, cable manufacturing relied on basic methods that involved simple assembly and standard materials. However, with the rise of data-hungry applications, the industry has shifted towards innovative techniques that enhance performance and reliability. Techniques such as precision extrusion and advanced wire drawing have emerged, allowing manufacturers to produce cables that minimize signal loss and improve overall durability.

Moreover, the integration of smart materials and manufacturing processes has played a pivotal role in the evolution of cable fabrication. Companies are now utilizing techniques like 3D printing and automated assembly lines to create customized and more efficient cable designs. These modern approaches not only reduce production times but also allow for greater flexibility in meeting specific client requirements. Additionally, the emphasis on sustainability has led to the development of eco-friendly materials and manufacturing processes, setting a new standard in the industry. As technology continues to advance, cable fabrication techniques will likely evolve even further, ensuring that connectivity solutions keep pace with the demands of modern applications.

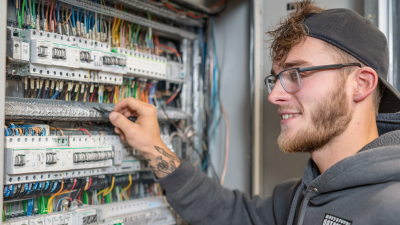

The cable manufacturing industry has witnessed significant innovations that enhance efficiency and reduce production costs. One major advancement is the introduction of automated manufacturing processes, which streamline cable assembly and ensure consistency in quality. Automation not only speeds up production but also minimizes human error, allowing manufacturers to meet rising demand without compromising on standards.

Tips: When considering automation in your production line, assess the compatibility of existing equipment with new technologies. Investing in training for your workforce can also maximize the benefits of automation by ensuring employees can effectively operate and maintain new systems.

Another innovation is the development of new materials that improve cable performance and durability. These materials are often lighter, stronger, and more resistant to environmental factors, making them ideal for modern technological applications. Additionally, incorporating smart technologies into cables can lead to better monitoring and maintenance, further enhancing operational efficiency.

Tips: When selecting materials for cable production, prioritize options that maintain performance under various conditions. Conducting thorough tests on new materials can help identify the best fit for specific applications and extend the lifespan of the cables.

The growing emphasis on sustainability in cable production is increasingly driven by the global shift towards renewable energy sources such as solar, wind, and hydropower. As the demand for clean energy rises, so does the need for efficient and eco-friendly cable solutions that can support these technologies. Manufacturers are now focusing on integrating sustainable practices into their operations, aiming to minimize their environmental footprint while meeting the evolving demands of the market. This growing focus on sustainability not only aligns with regulatory requirements but also appeals to environmentally conscious consumers.

Moreover, the landscape of cable manufacturing is undergoing significant transformations as we approach 2026. Trends such as the adoption of recycled materials, energy-efficient production processes, and advancements in cable technology are paving the way for a more sustainable future. Companies are increasingly prioritizing innovative material choices and manufacturing techniques that enhance their sustainability credentials, ensuring they remain competitive in a rapidly changing market. As the sector adapts to these trends, the cable industry is set to play a vital role in supporting the global transition towards renewable energy and sustainable practices.

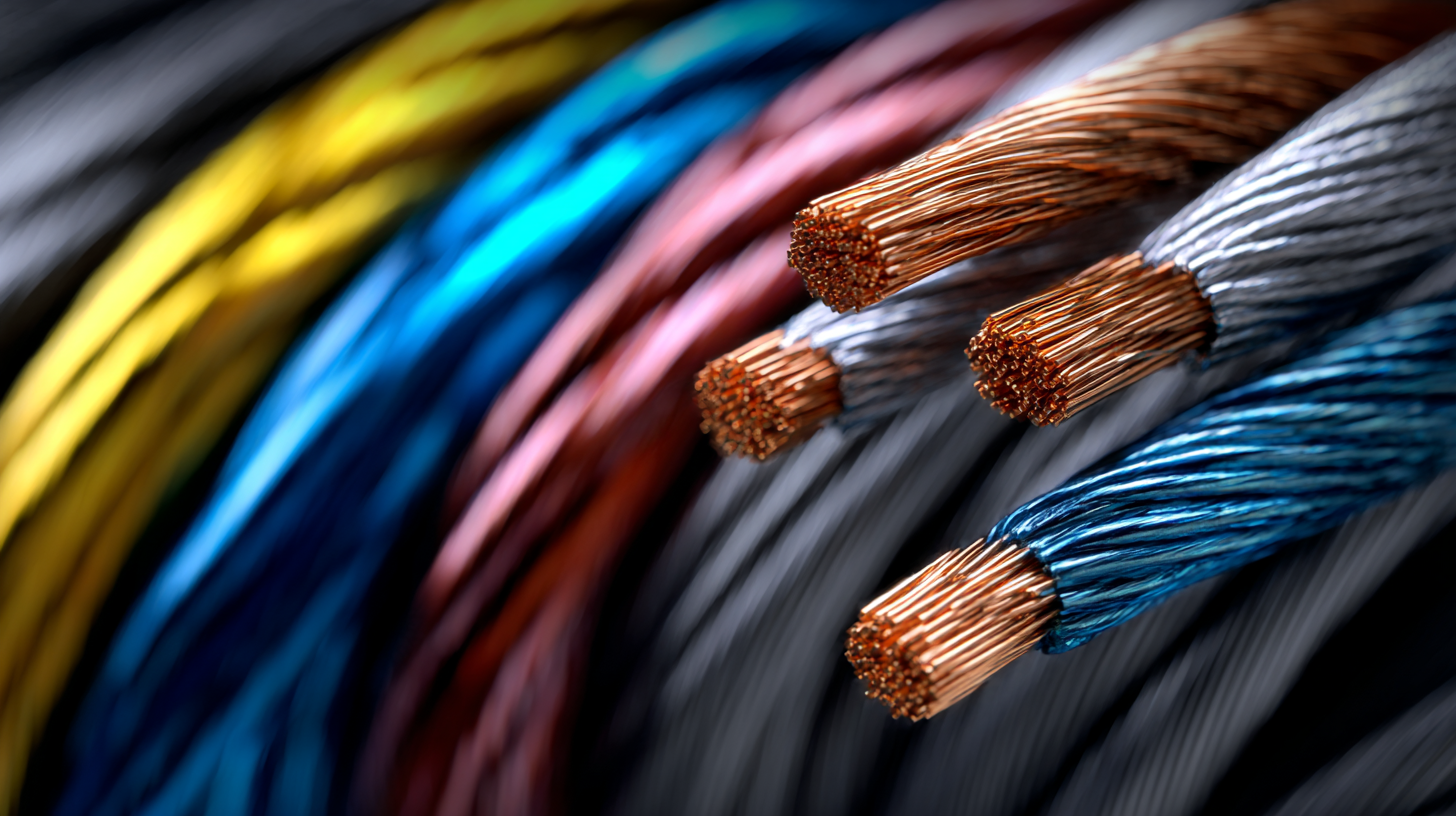

Innovations in cable fabrication have significantly transformed various industries by incorporating advanced materials that enhance cable performance. These materials, such as high-strength polymers, composite fibers, and metallic alloys, contribute to improved electrical conductivity, reduced weight, and increased durability. For instance, the introduction of thermoplastic elastomers allows for greater flexibility and resistance to environmental factors, making cables more reliable in harsh conditions.

Furthermore, the strategic use of nanotechnology in cable production is paving the way for next-generation performance. By integrating nanoparticles into the materials, manufacturers can achieve better thermal management and lower signal attenuation. This advancement is particularly crucial for high-speed data transmission applications, where effective heat dissipation and signal integrity are paramount. As these advanced materials continue to evolve, they promise to further elevate the efficiency and functionality of cables, meeting the increasing demands of modern technology.

As the demand for advanced communication and power transmission grows, the future of cable fabrication technologies is poised for remarkable advancements. Data from a recent market report by ResearchAndMarkets indicates that the global cable manufacturing market is projected to reach approximately $210 billion by 2025, reflecting an annual growth rate of around 6%. Innovations such as smart cables and the integration of fiber optics into traditional cable systems are at the forefront of meeting these rising needs. Embracing environmentally friendly materials and manufacturing processes is also on the rise, driven by heightened awareness of sustainability.

Tip: To stay ahead in the cable fabrication industry, companies should invest in research and development to adapt to these emerging trends. Collaborating with tech firms to explore the potential of IoT in enhancing the functionality of cables can lead to groundbreaking products.

Looking further ahead, the shift towards renewable energy sources and electric vehicles will necessitate cables that can handle higher voltages and greater flexibility. The International Energy Agency's report suggests that the shift to electric vehicles alone could increase global demand for power cables by 20% annually. This creates a pressing opportunity for innovation in cable materials and designs to accommodate modern technology's evolving landscape.

Tip: Engaging with industry experts and attending relevant trade shows can provide valuable insights into future trends and technologies that will influence cable fabrication. Keeping an eye on governmental policies regarding green initiatives can also guide strategic decisions in product development.