In the rapidly evolving landscape of electrical harness design and manufacturing, innovative techniques have emerged to enhance efficiency and effectiveness. The integration of "digital + best" methodologies is paving the way for a transformative approach in the industry, focusing on the optimization of electrical harness systems. These systems, critical for the connectivity of various components in automotive and aerospace applications, demand precision and reliability.

By leveraging cutting-edge technologies such as advanced simulation software, automated manufacturing processes, and real-time data analytics, engineers can streamline workflows, reduce production time, and improve overall product quality. This introduction will explore how these innovative techniques not only address the complexities of electrical harness design but also illustrate the importance of incorporating best practices to meet the dynamic needs of modern applications. Ultimately, a shift towards such advanced strategies promises to redefine manufacturing paradigms and drive the industry towards a more sustainable and efficient future.

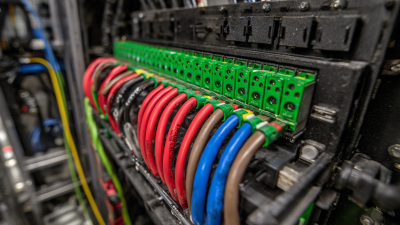

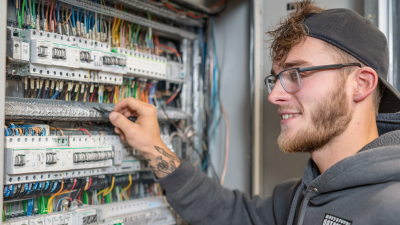

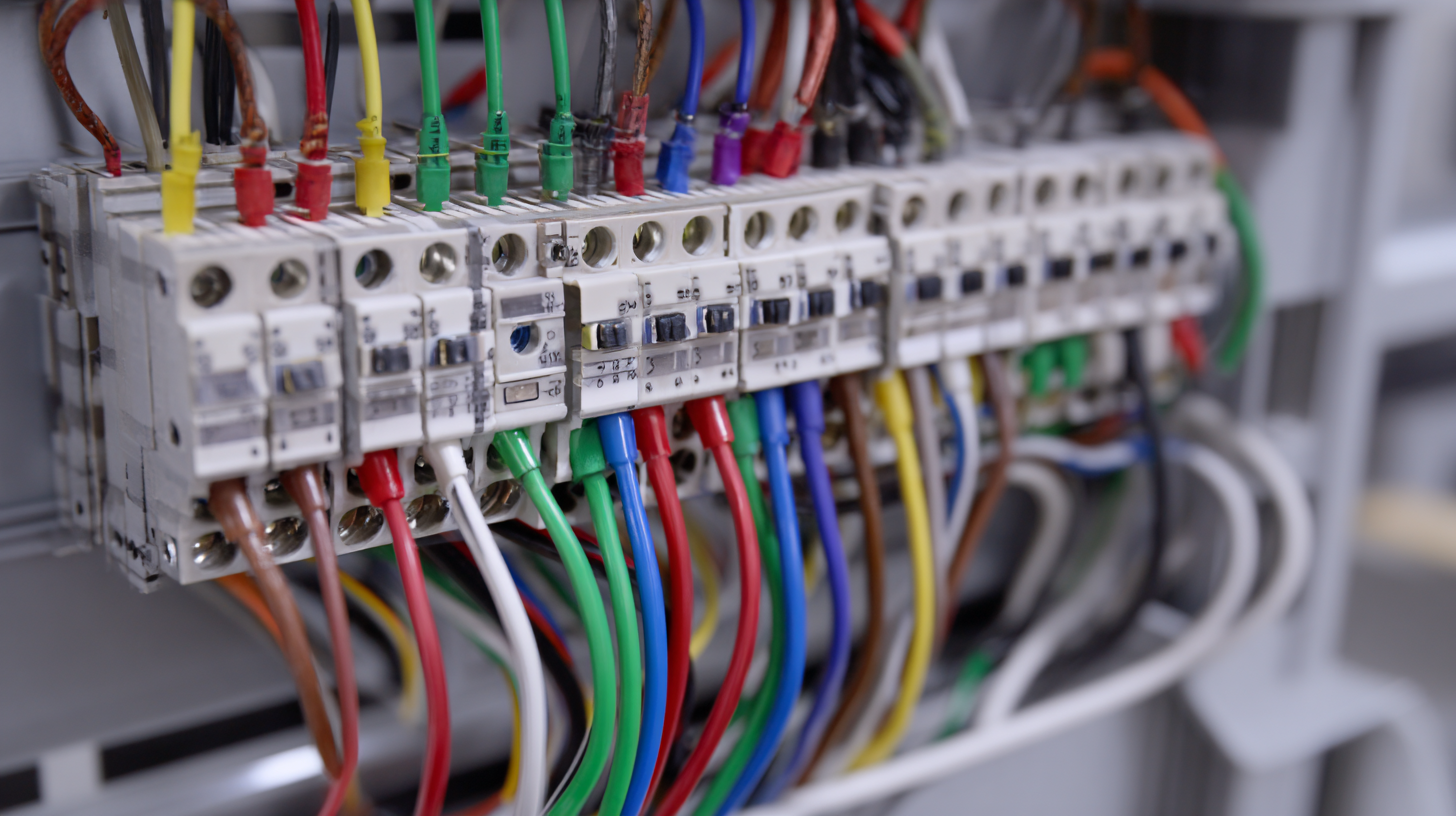

The integration of Computer-Aided Design (CAD) software in the electrical harness design process has revolutionized the way engineers approach their work. By utilizing sophisticated modeling tools, designers can create intricate harness layouts that optimize both functionality and space. CAD software enables the visualization of complex wiring systems, allowing for easier identification of potential issues before physical production begins. This not only enhances accuracy but also significantly reduces the risk of costly errors during the manufacturing phase.

Moreover, CAD software streamlines communication among team members, facilitating real-time collaboration and instant updates. Design iterations can be made swiftly, ensuring that every stakeholder remains aligned with the project's objectives. As a result, time-to-market for new electrical harnesses is notably improved. Additionally, advanced simulation features in CAD applications enable engineers to test and validate designs under various conditions, further enhancing reliability and performance. The adoption of these innovative techniques ultimately leads to more efficient electrical harness manufacturing, driving innovation in various industries reliant on cutting-edge electrical systems.

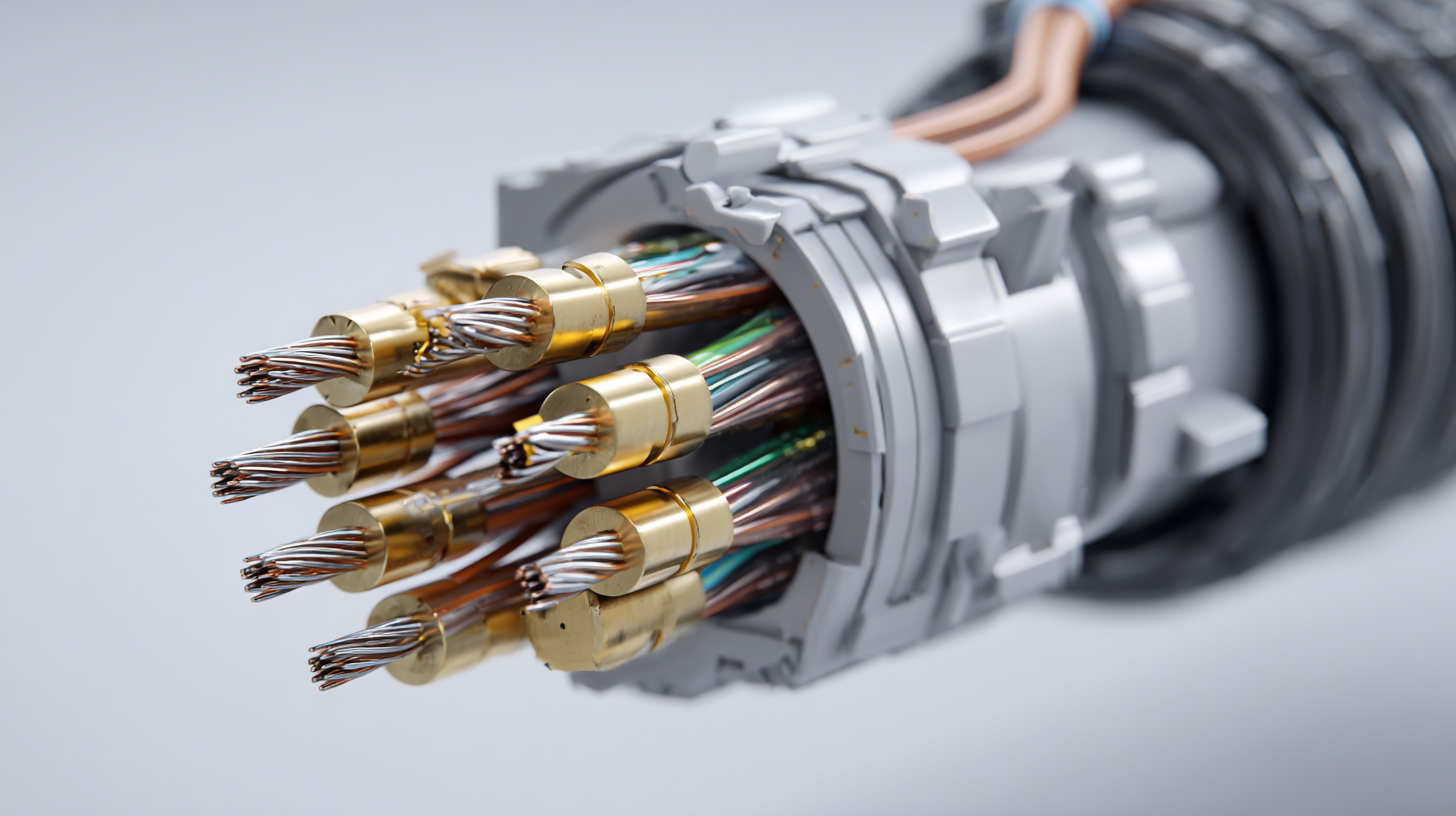

The advancement of electrical harness design and manufacturing has sparked a revolution in the use of advanced materials. By utilizing lightweight composites and high-performance polymers, manufacturers can reduce the overall weight of harnesses while significantly improving their durability. These materials not only contribute to performance enhancements in automotive and aerospace applications but also support sustainability efforts by reducing fuel consumption and emissions.

Tips for selecting advanced materials include prioritizing those with high tensile strength and resistance to environmental factors such as moisture and extreme temperatures. Additionally, consider the cost-effectiveness of these materials to ensure that the transition does not adversely affect the budget.

Moreover, incorporating innovative manufacturing processes like 3D printing can further optimize the design and production of electrical harnesses. This technology allows for intricate designs that can enhance functionality without adding unnecessary weight. As industries move toward more efficient solutions, embracing these techniques will be crucial for staying competitive in the market.

Remember, experimenting with different combinations of advanced materials can lead to unique solutions tailored specifically to your project needs. Always conduct thorough testing to validate performance under realistic conditions.

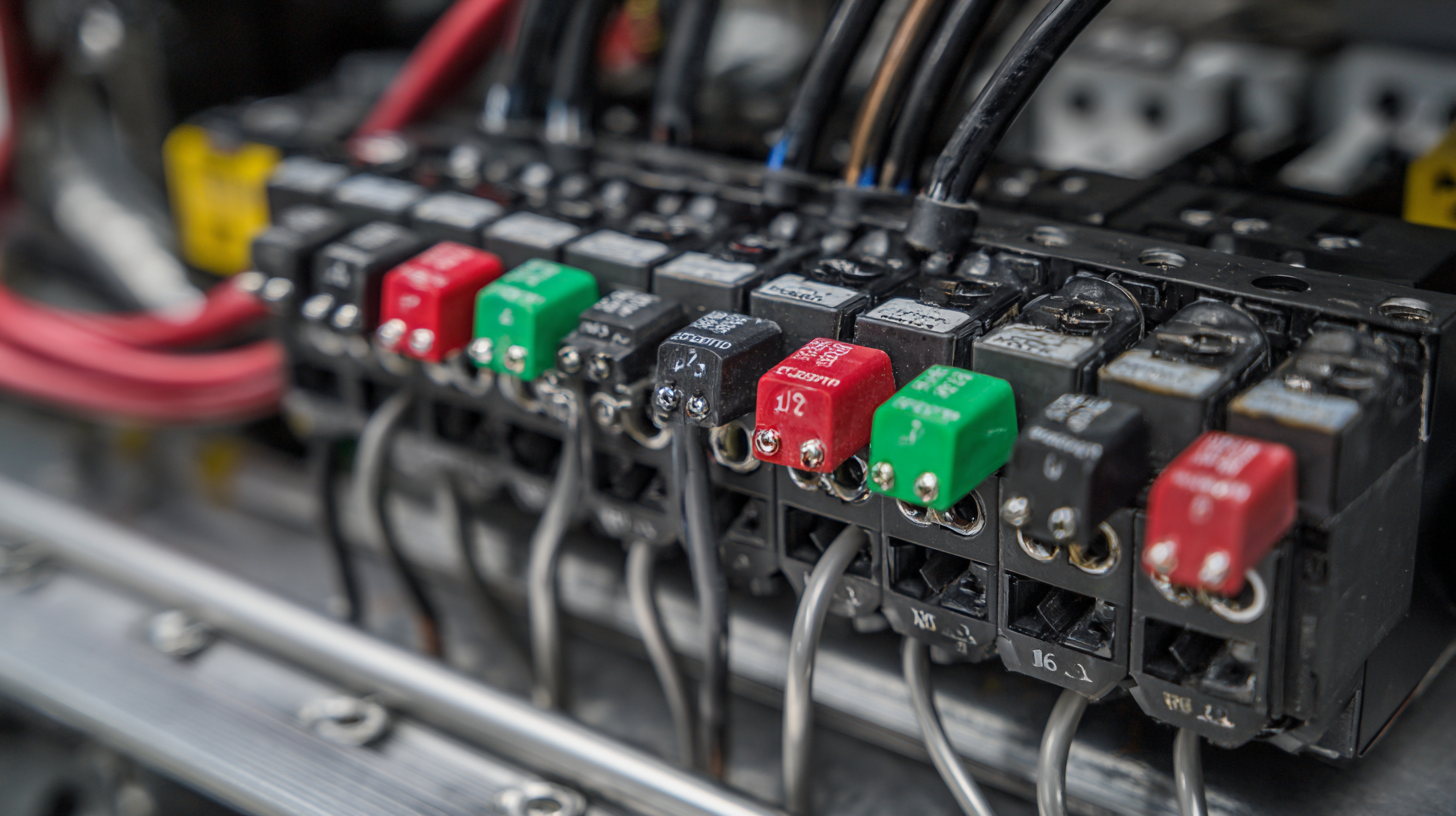

The design and manufacturing of electrical harnesses have witnessed transformative advancements, driven by the adoption of innovative techniques. One crucial aspect of this evolution is the implementation of simulation tools, which have significantly enhanced error reduction during the harness manufacturing process. By utilizing simulation software, designers can visualize and analyze the electrical paths, ensuring that the layout meets both functional and aesthetic requirements before physical production begins.

The design and manufacturing of electrical harnesses have witnessed transformative advancements, driven by the adoption of innovative techniques. One crucial aspect of this evolution is the implementation of simulation tools, which have significantly enhanced error reduction during the harness manufacturing process. By utilizing simulation software, designers can visualize and analyze the electrical paths, ensuring that the layout meets both functional and aesthetic requirements before physical production begins.

These simulation tools not only streamline the design phase but also facilitate early identification of potential issues, such as electromagnetic interference or mechanical constraints. By creating virtual prototypes, engineers can run various scenarios and adjust designs in real time, thereby minimizing costly revisions and delays. This proactive approach leads to a more robust design, ultimately enhancing the reliability and performance of the final product. Embracing these innovative techniques enables manufacturers to improve production efficiency and maintain high-quality standards in electrical harness design.

The integration of IoT solutions for real-time monitoring in the food and beverage industry is transforming the approach to production efficiency amidst the rise of Industry 4.0 technologies. With advanced analytics becoming more prevalent, manufacturers are leveraging data-driven insights to optimize their operations. According to reports, the energy management systems market is expected to achieve significant growth, with projections showing an increase that could see the market size reach substantial figures by 2032. This emphasizes the industry's movement towards sustainability and efficiency, considering that the food sector is responsible for a considerable share of greenhouse gas emissions.

Moreover, the electrical SCADA market is projected to grow significantly, with a compound annual growth rate of 6.82% from 2024 to 2030, indicating a robust demand for intelligent monitoring solutions. The adoption of IoT, AI, and cloud computing within manufacturing is facilitating a new interactive approach to big data, pushing for smarter and optimized operations. Implementing these advanced technologies not only helps in reducing energy consumption but also plays a critical role in achieving sustainable practices in the food and beverage industry, where optimizing resource management is crucial for future competitiveness.

The integration of modular design strategies in electrical harness design and manufacturing offers significant advantages in terms of customization and flexibility. By adopting a modular approach, engineers can create harness systems that are not only easier to assemble but also adaptable to a wide range of applications. This flexibility allows for the rapid incorporation of new technologies and evolving requirements, paralleling trends seen in other fields such as modular buses in urban transit systems, which can dynamically adjust capacity based on demand.

Furthermore, the emphasis on modularity can enhance collaboration between teams, enabling a more efficient workflow. As seen in various sectors, including e-commerce platforms, modular designs facilitate seamless updates and integration of new components, ensuring that products remain competitive in a fast-paced market. This adaptability not only streamlines the manufacturing process but also supports the creation of highly customized solutions tailored to specific client needs, reflecting the growing consumer demand for personalized experiences.