In the competitive landscape of modern manufacturing, optimizing production efficiency is crucial for sustaining profitability and meeting market demands. Advanced wire harness manufacturing equipment plays a pivotal role in achieving this optimization, particularly as the global wire harness market is projected to reach $33.52 billion by 2027, growing at a CAGR of 6.4% from 2020 to 2027, according to a recent market research report. This surge in demand underscores the necessity for manufacturers to invest in cutting-edge technologies that enhance production speed, precision, and flexibility. By leveraging innovations such as automated assembly systems and precision cutting tools, companies can significantly reduce labor costs and minimize errors, ultimately leading to more streamlined operations. As organizations look to improve their competitive edge, understanding how to effectively integrate and utilize wire harness manufacturing equipment will be essential for driving efficiency and success in the rapidly evolving marketplace.

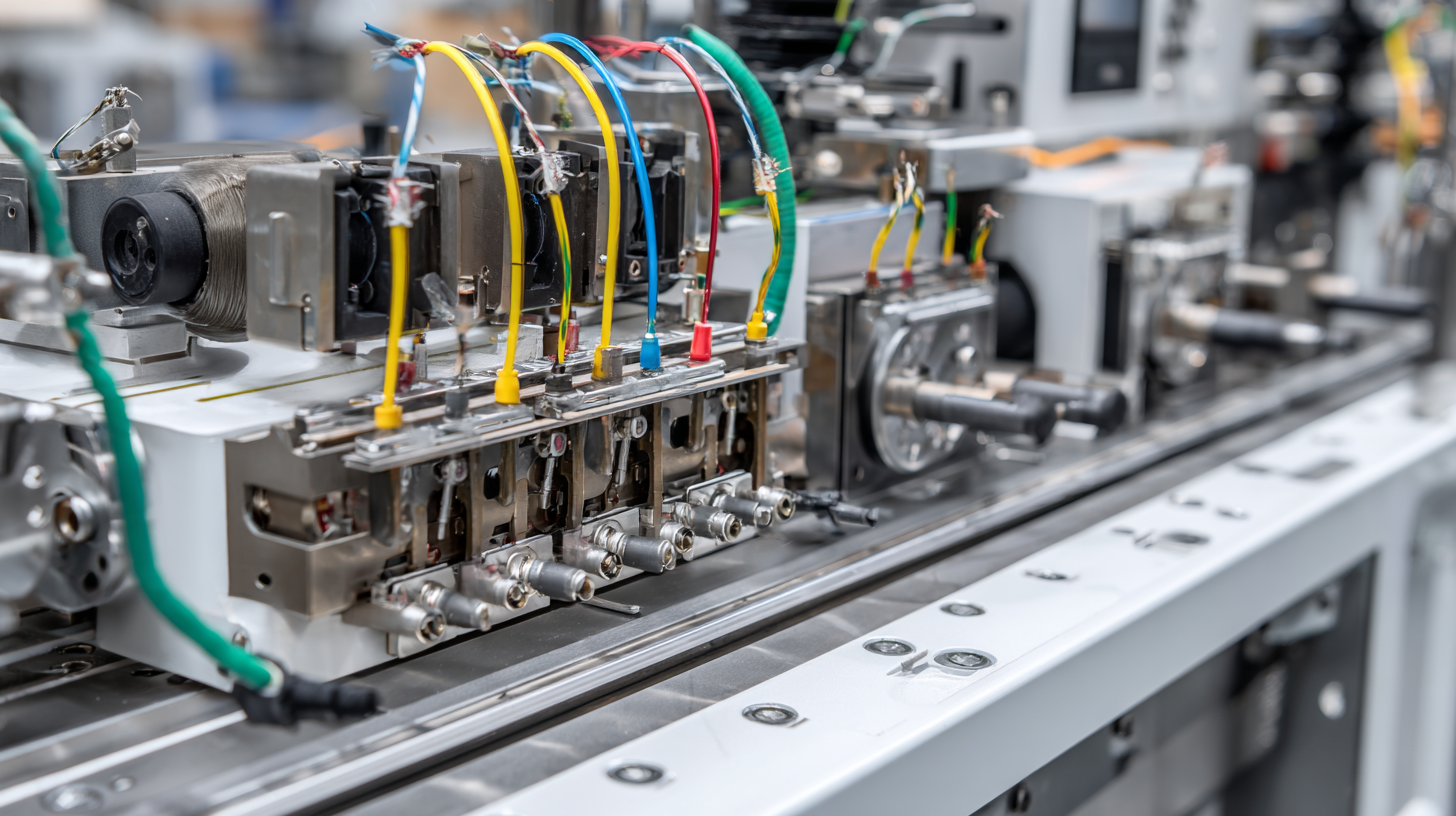

Advanced wire harness manufacturing equipment plays a crucial role in optimizing production efficiency within the automotive industry. As the backbone of vehicle electrical systems, wire harnesses consist of various components, including connectors made from copper and insulated wires. Innovations in manufacturing technology have greatly enhanced the precision and speed of wire harness production, allowing for the rapid development of complex wiring systems that meet the demands of traditional and electric vehicles alike. Recent reports indicate that the global automotive wire harness market is expected to reach approximately $58 billion by 2025, driven by the increasing proliferation of electric and hybrid vehicles.

Moreover, the rise of electric vehicles (EVs) has led to a significant shift in the wire harness manufacturing landscape. Local suppliers in China have established strong partnerships with domestic EV manufacturers, enabling them to leverage advanced equipment and techniques to produce high-voltage wire harnesses essential for electric drivetrains. By utilizing automated assembly lines and state-of-the-art testing machinery, manufacturers can ensure that their wire harnesses not only meet safety and performance standards but also deliver increased efficiency in production processes. In 2022, a notable supply chain analysis pointed out that suppliers capable of integrating advanced technology into their production workflows reported a 30% reduction in manufacturing lead times, underscoring the importance of adopting cutting-edge equipment in the wire harness sector.

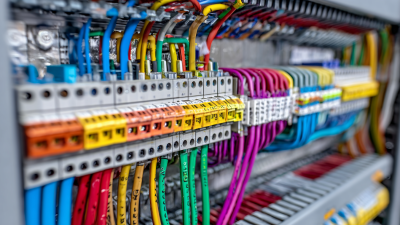

When optimizing production efficiency in wire harness manufacturing, choosing the right tools is crucial. Key features to look for in manufacturing equipment include precision, flexibility, and automation capabilities. According to a report by Grand View Research, the global wire harness market is expected to reach $173.48 billion by 2027, driven by the increasing demand in automotive and industrial applications. Advanced machines that offer automated cutting, stripping, and crimping not only enhance accuracy but also significantly reduce production times and labor costs.

Another important feature is the adaptability of the equipment. With the growing trend towards custom and complex wire harness assemblies, manufacturers need tools that can easily accommodate various sizes and types of wires. A study from MarketsandMarkets indicates that the wire harness manufacturing equipment market will grow at a CAGR of 6.1% from 2020 to 2025, highlighting the necessity for devices that can efficiently handle evolving customer needs without the need for extensive reconfiguration or downtime. Investing in advanced wire harness manufacturing equipment with these key features can lead to greater operational efficiency and competitive advantage in the industry.

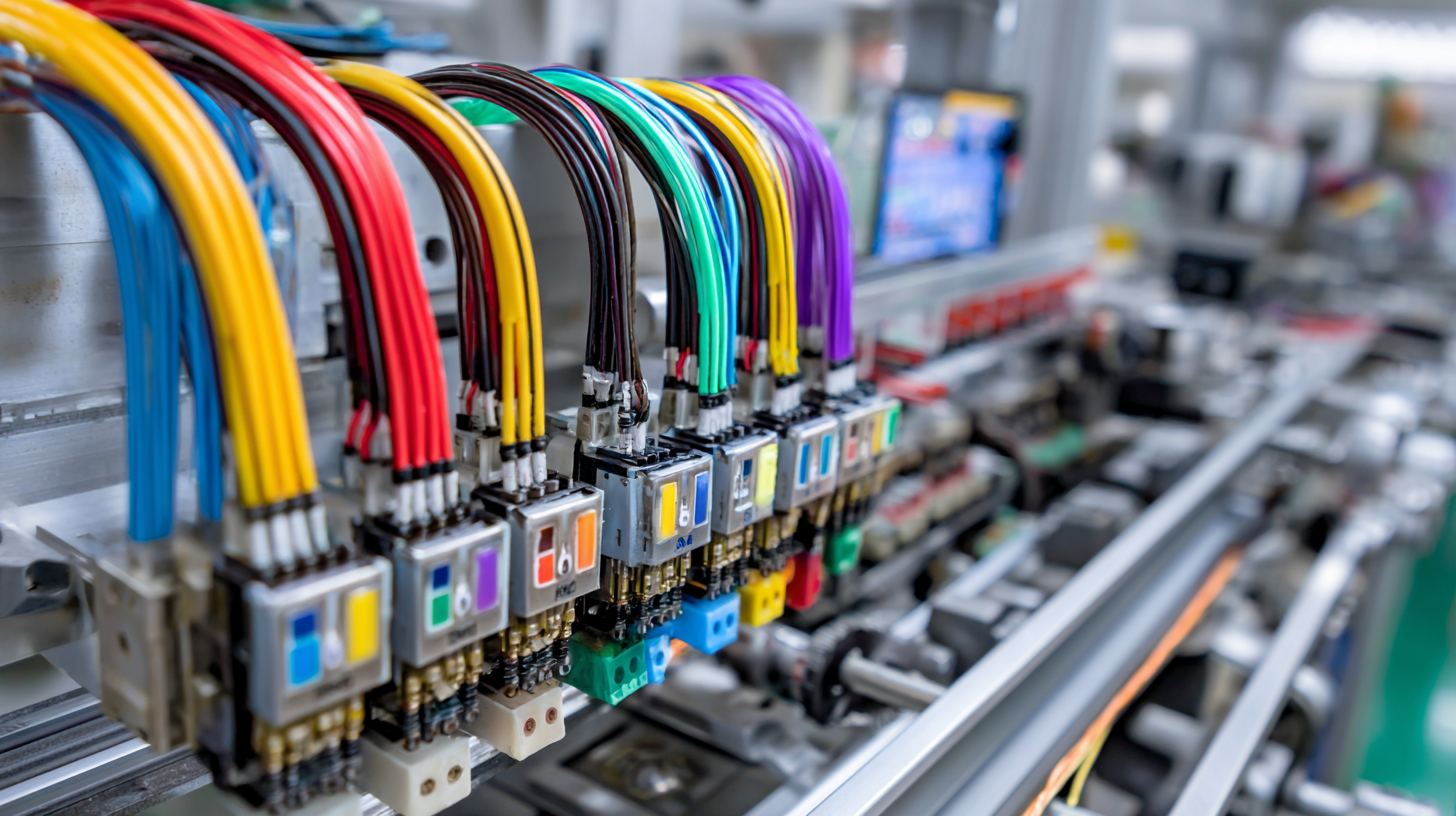

Implementing automation in wire harness manufacturing can significantly enhance production efficiency, addressing the growing demands of modern industries. By utilizing advanced manufacturing equipment, companies can reduce labor costs by up to 30%, as noted in a recent report by the National Wire Harness Manufacturers Association (NWHMA). Automation allows for a streamlined workflow, minimizing the risk of human error and increasing precision in wire processing, assembly, and testing.

Moreover, the integration of automated systems can increase production speeds by approximately 50%, a figure supported by industry analysis from Automation World. The use of automated cutting, crimping, and packaging machines leads to faster turnaround times while maintaining high-quality standards. As a result, manufacturers not only meet customer demands more effectively but also enhance their overall competitiveness in the market.

Investing in automation is not just a trend but a necessary evolution for wire harness manufacturing to thrive in an increasingly demanding landscape.

Regular maintenance of advanced wire harness manufacturing equipment is crucial for ensuring optimal production efficiency. First, establishing a consistent maintenance schedule can help identify potential issues before they escalate into costly breakdowns. Routine checks should include inspecting mechanical components, calibrating settings, and updating software to prevent unexpected downtimes.

Furthermore, training operators on the proper handling and operation of machinery ensures they can spot irregularities early and address them before they compromise the manufacturing process.

Furthermore, training operators on the proper handling and operation of machinery ensures they can spot irregularities early and address them before they compromise the manufacturing process.

In addition to routine maintenance, employing preventative strategies can enhance equipment longevity. Implementing a monitoring system that tracks performance metrics allows manufacturers to analyze data and predict when specific parts may need replacement. Moreover, creating a spare parts inventory ensures that critical components are readily available, reducing the time required for repairs. Emphasizing these best practices not only optimizes operational efficiency but also fosters a proactive maintenance culture within the manufacturing facility, ultimately driving productivity and reducing overall costs.

In today’s competitive industrial landscape, optimizing production efficiency is crucial for manufacturers, especially in wire harness production. Training the workforce to utilize advanced manufacturing equipment effectively can significantly enhance operational performance. According to industry reports, companies that invest in workforce training see a 20% increase in capacity utilization rates. This metric indicates the percentage of potential output being utilized and can highlight inefficiencies within production processes. By addressing the skills gaps through structured training programs, manufacturers can not only improve equipment usage but also maximize their overall productivity.

Moreover, human–machine harmonization plays a pivotal role in modern biopharma production. As advanced analytics and artificial intelligence become prevalent, the importance of effectively training employees to interact with these technologies cannot be overstated. Studies show that organizations embracing AI-enhanced training programs can achieve up to a 30% improvement in yield. This synergy between skilled workers and sophisticated machines allows for a more agile production environment, where both human talent and technology contribute to higher profitability and efficiency. Investing in the continuous development of your workforce is essential for leveraging the full potential of advanced manufacturing equipment.

| Equipment Type | Efficiency Rating (%) | Training Hours Required | Maintenance Frequency (Months) | Employee Satisfaction Score |

|---|---|---|---|---|

| Automatic Wire Cutter | 85 | 10 | 6 | 4.5 |

| Crimping Machine | 90 | 8 | 5 | 4.8 |

| Wire Stripping Machine | 80 | 12 | 8 | 4.4 |

| Laser Marker | 88 | 15 | 12 | 4.6 |

| Connector Insertion Tool | 92 | 9 | 7 | 4.7 |