In today's highly competitive manufacturing landscape, optimizing the cable fabrication process is crucial for companies looking to enhance efficiency and product quality. According to a recent report by Research and Markets, the global cable assembly market is expected to reach $131.95 billion by 2025, growing at a CAGR of 7.65%. This significant growth underscores the importance of refining fabrication techniques to meet burgeoning demand while maintaining high standards. As consumers and industries increasingly rely on reliable and high-quality cables, streamlining the production process becomes imperative. By adopting best practices and advanced technologies in cable fabrication, manufacturers can not only reduce operational costs but also ensure that their products exceed customer expectations in durability and performance. This guide will explore essential strategies to perfect your cable fabrication process, ultimately aiming to propel your business to new heights in an evolving market.

In the realm of cable fabrication, recognizing and addressing common challenges is essential for achieving enhanced quality and efficiency. One significant hurdle is the inconsistency in raw materials quality. Variations in insulation types, conductor materials, or manufacturing defects can lead to significant discrepancies in the final product. Implementing robust quality control measures—such as sourcing materials from reputable suppliers and conducting thorough inspections—can mitigate these issues and uphold product standards.

Another challenge is the inefficiency often present in the production process itself. Many fabricators struggle with complex workflows that lead to bottlenecks and increased lead times. Streamlining the production line by adopting modern technologies, such as automated machinery and real-time monitoring systems, can help to reduce these inefficiencies. This not only boosts overall productivity but also ensures a more consistent output, ultimately leading to higher quality cables that meet rigorous industry standards. By focusing on these common challenges, manufacturers can make informed changes that enhance both the efficiency and quality of their cable fabrication processes.

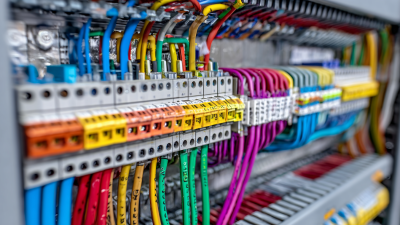

The modern cable fabrication process is increasingly influenced by automation technologies, which play a pivotal role in enhancing both efficiency and quality. By integrating advanced machinery and software solutions, manufacturers can streamline operations, reduce manual errors, and optimize production speed. Key technologies such as robotic arms for precise assembly, automated cutting machines, and intelligent inventory management systems allow for a more cohesive workflow. This not only minimizes downtime but also ensures that products meet stringent quality standards.

Incorporating automation in cable fabrication also facilitates better data collection and analysis. With IoT-enabled devices, real-time monitoring of equipment and processes becomes feasible, leading to faster decision-making and proactive maintenance. Moreover, utilizing software systems that leverage artificial intelligence can predict demand trends, customize orders, and manage supply chains effectively. As the industry continues to evolve, adopting these automation technologies will be crucial for companies looking to stay competitive while maintaining high-quality outputs.

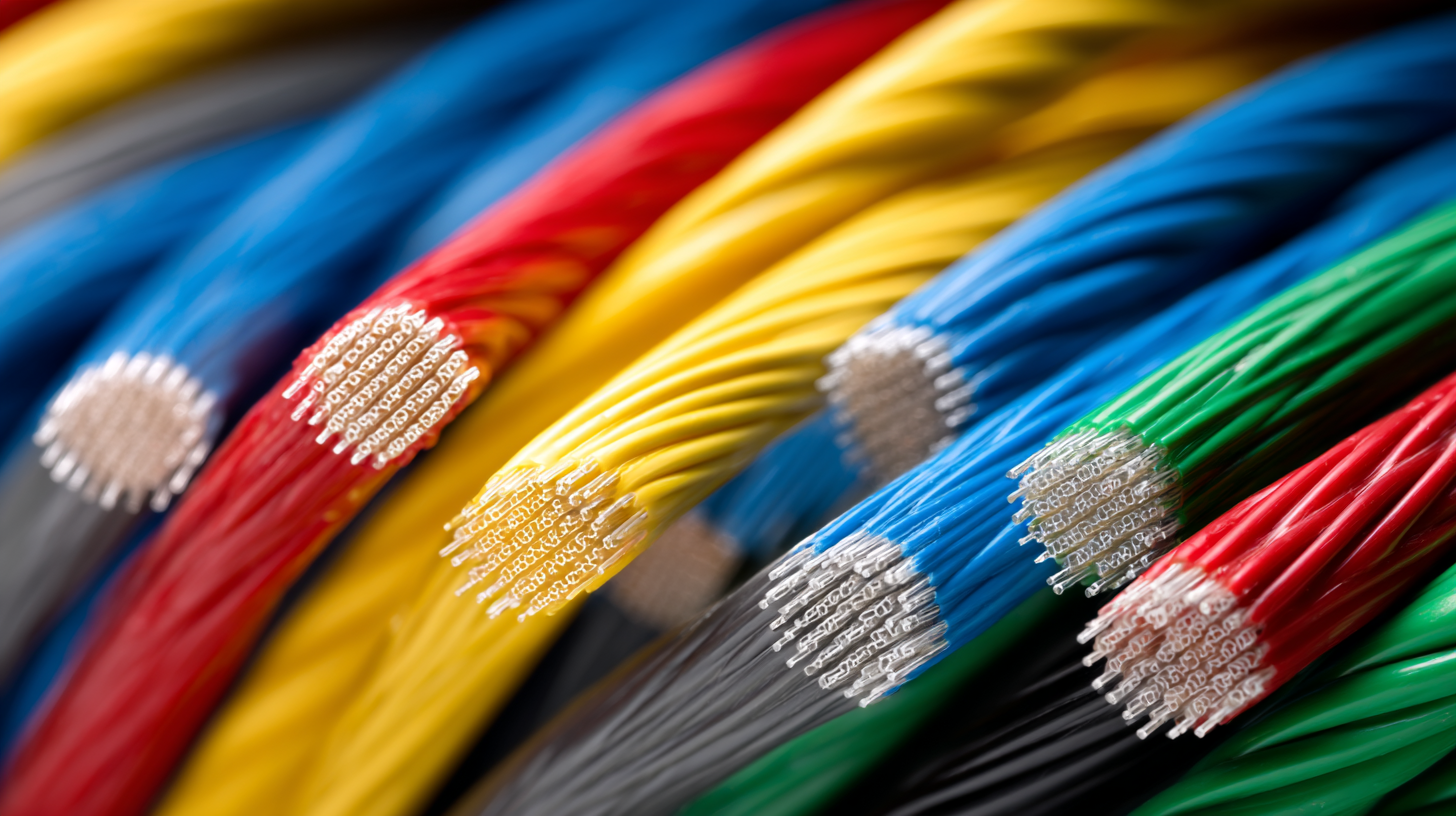

In the cable fabrication industry, material selection plays a crucial role in determining the durability and efficiency of the final product. According to a report by MarketsandMarkets, the global cable market is expected to reach $260 billion by 2025, driven by the rising demand for renewable energy and smart infrastructure. Choosing the right materials not only enhances the performance of cables but also significantly impacts manufacturing costs.

To improve both durability and efficiency, manufacturers should consider the use of high-quality copper or aluminum conductors, which provide excellent conductivity and resistance to corrosion. In fact, studies show that cables made with high-purity copper can lower energy losses by up to 30% compared to those made from lower-grade materials. Additionally, investing in thermoplastic insulating materials can lead to increased thermal stability and reduced risk of deterioration under high temperatures, ensuring a longer lifespan for the cables.

Furthermore, incorporating advancements in composite materials can enhance both flexibility and tensile strength, essential for modern applications. A recent analysis by Research and Markets indicates that the use of composite materials in cable fabrication can improve mechanical properties by up to 25%, providing manufacturers with a competitive edge in a rapidly evolving market. Emphasizing these material choices not only boosts efficiency but also aligns with the industry's push towards sustainability and innovation.

In the fast-paced world of cable fabrication, the integration of data analytics into production processes has emerged as a game-changer. By leveraging data analytics, manufacturers can monitor every aspect of their production lines in real-time, identifying inefficiencies and potential bottlenecks that could compromise quality. For instance, sensor technology can provide valuable insights into machine performance, helping engineers to predict maintenance needs before they result in costly downtime. This proactive approach not only boosts efficiency but also ensures a higher standard of product quality.

Furthermore, data analytics allows for a deeper understanding of variances in production. By analyzing historical data, manufacturers can pinpoint trends that may affect cable quality, such as material inconsistencies or variations in environmental conditions. Armed with this information, they can implement targeted strategies to address these issues, refining their fabrication processes to achieve more consistent results. As the industry continues to evolve, embracing data-driven methodologies will be essential for organizations looking to enhance their cable production performance and maintain a competitive edge.

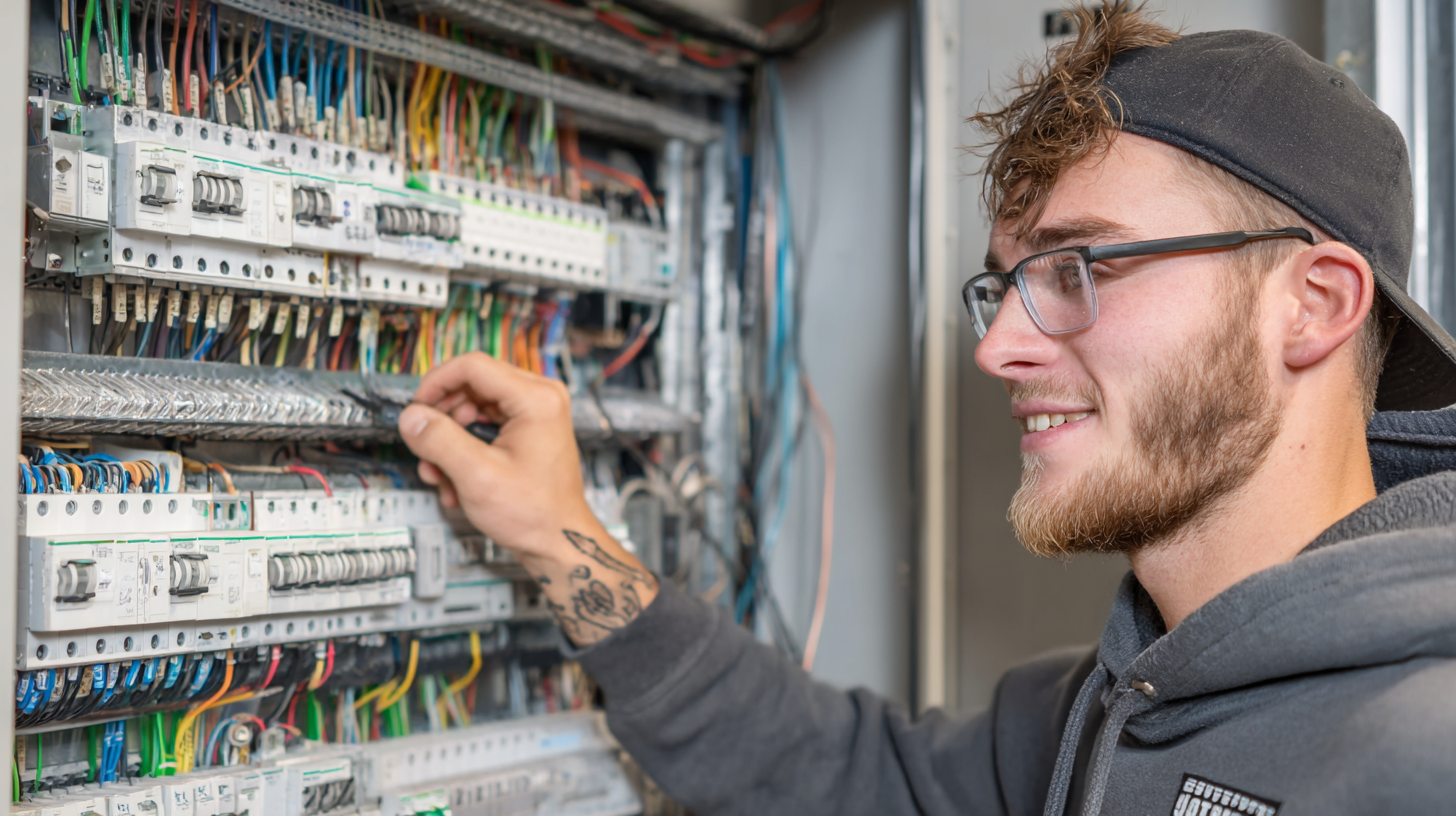

In today's fast-paced manufacturing environment, elevating employee training and skill development is crucial for enhancing production standards and overall efficiency. A robust training program goes beyond the basics; it focuses on creating a skilled workforce that can adapt to evolving technologies and methodologies. Recent trends highlight the importance of integrating innovative training approaches, such as game-based learning, which not only makes the process enjoyable but also significantly improves skill retention. By engaging employees in interactive formats, companies can foster a proactive learning culture that directly supports manufacturing quality and efficiency.

Moreover, initiatives to boost vocational education, particularly in advanced manufacturing sectors, are essential in bridging the skills gap often seen in the workforce. By prioritizing structured training programs that align with current industry demands, organizations can empower employees to meet the increasing complexities of modern manufacturing challenges. Not only does this lead to better individual performance, but it also enhances overall business growth, ensuring manufacturers stay competitive in the global landscape.

Investing in employee development is a strategic move that pays dividends in both efficiency and product quality.