Selecting the right electrical harness is a crucial step in the success of any project requiring electrical connectivity and functionality. An electrical harness, which serves as a bundled assembly of wires, connectors, and terminals, plays a vital role in ensuring safe and efficient electrical transmission. As projects vary widely in scope, purpose, and environment, understanding the specific requirements of your application is essential for making an informed choice. This guide will walk you through key considerations such as the type of wire materials, insulation options, and connector styles that align with your project needs. By the end of this article, you will have a comprehensive understanding of how to effectively select the appropriate electrical harness, avoiding common pitfalls and enhancing the reliability and performance of your project.

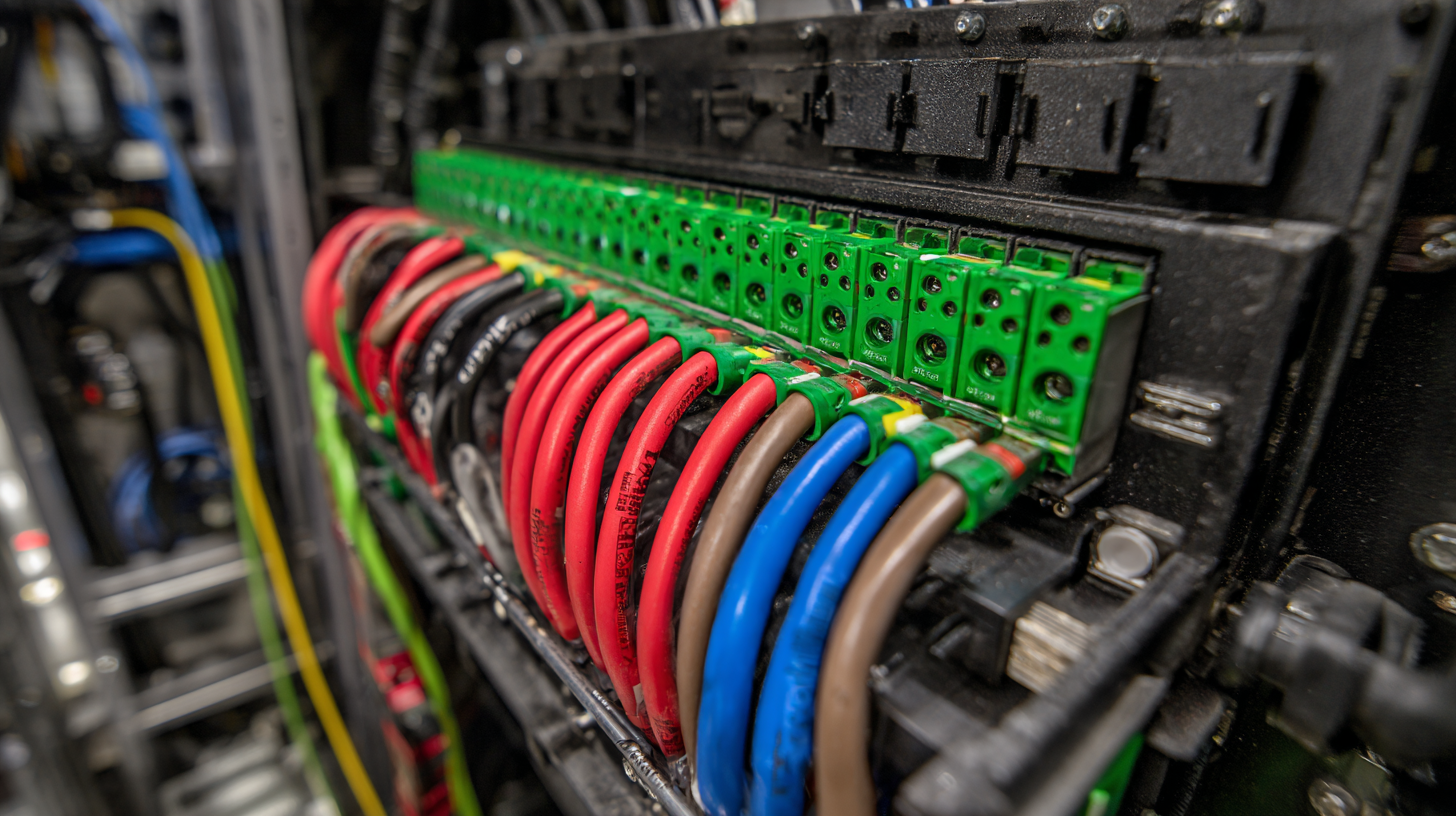

When selecting the right electrical harness for your project, it's crucial to understand the various types available. Electrical harnesses come in several forms, including flat cable harnesses, round cable harnesses, and custom-designed harnesses. Flat cable harnesses are ideal for space-constrained applications, as they provide a compact design that facilitates easy routing and installation. On the other hand, round cable harnesses offer greater durability and flexibility, making them suitable for applications exposed to harsh conditions.

Tips for selecting the right harness include carefully considering the environmental factors it will be subjected to. For example, if the harness will be used in a high-temperature area, choose insulation materials that can withstand heat. Additionally, analyze the specific needs of your electrical components; be sure to account for the number of wires and their required gauge to ensure optimal performance and safety.

Another important aspect is the connectors used in your harness. Different connectors serve different functions, and selecting the right one can impact both performance and reliability. Consider using connectors that are weather-resistant for outdoor applications, or locking connectors for vibration-prone environments. By focusing on these fundamentals, you can make informed decisions that will enhance your project's efficiency and longevity.

| Harness Type | Applications | Materials Used | Advantages | Disadvantages |

|---|---|---|---|---|

| Multi-Conductor Harness | Automotive, Aerospace | Copper, PVC insulation | Compact design, multiple circuits | Complex to repair |

| Custom Harness | Industrial equipment, Robotics | Various - tailored to needs | Tailored for specific requirements | Higher cost and longer lead time |

| Ribbon Cable Harness | Consumer electronics, Data transmission | Flat cable, Insulating materials | Space-saving, flexible | Less durable under stress |

| Wire-to-Board Harness | Computers, Home appliances | Copper wires, Connectors | Easy connection to circuit boards | Limited current capacity |

| Power Distribution Harness | HVAC systems, Industrial machines | High gauge copper, Heat-resistant material | Supports higher current loads | Bulkier design |

When selecting the right electrical harness for your project, several key factors must be taken into consideration. Firstly, the specifications of your project play a crucial role. Understanding the voltage, current requirements, and environmental conditions – such as temperature extremes, moisture exposure, and abrasion risks – will help you determine the appropriate materials and designs needed for durability and performance.

Another vital aspect is the connector compatibility. Different connectors serve various functions and have distinct pin configurations. Ensuring that your electrical harness accommodates the required connectors can prevent complications during assembly and enhance the overall reliability of the system. Additionally, consider the ease of installation and maintenance; a harness designed for efficiency can significantly reduce time and labor costs during both setup and potential future repairs.

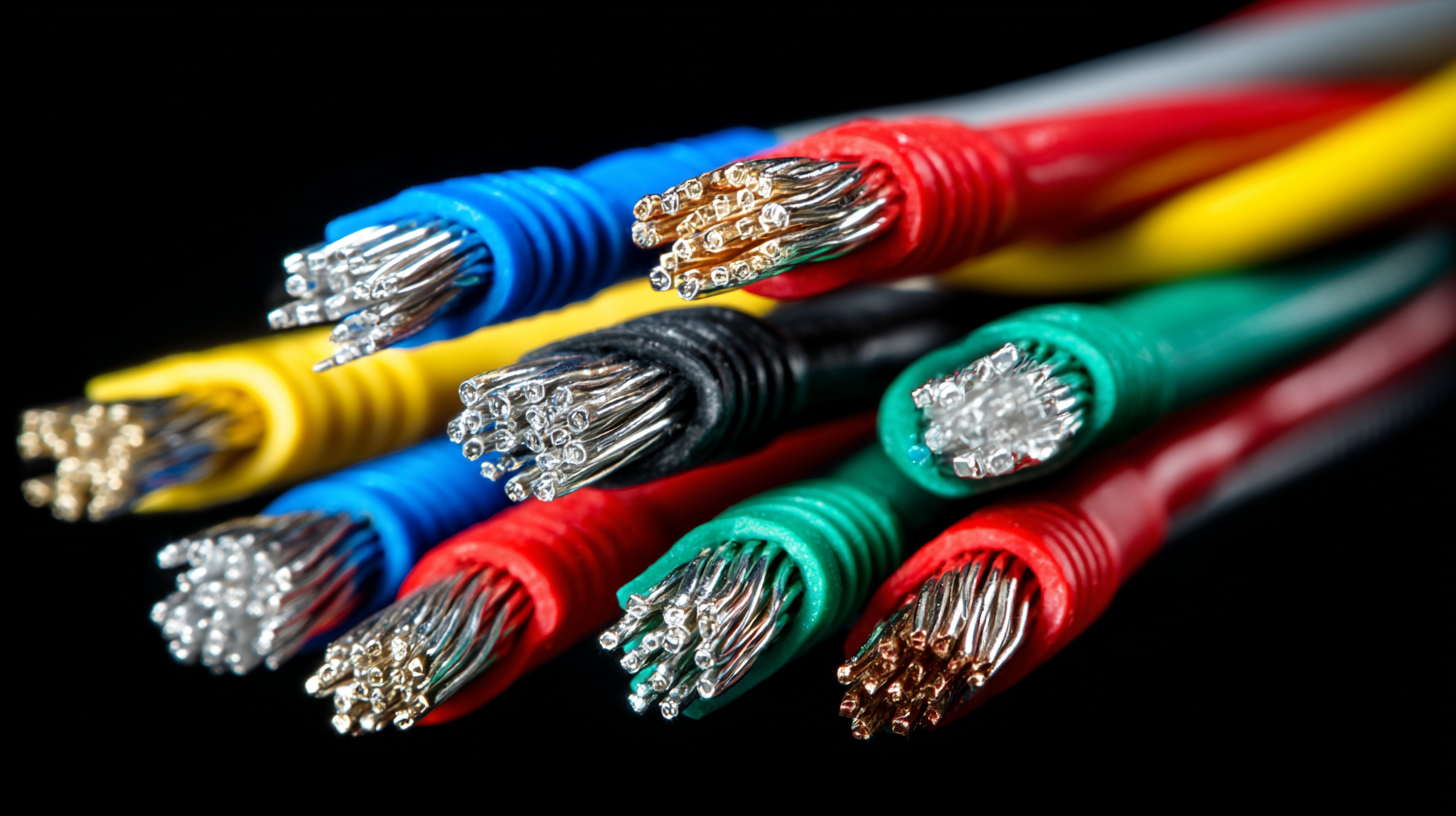

When selecting the right electrical harness for a project, understanding the various materials available and their specific applications is crucial. Common materials include PVC, rubber, and silicone.

PVC harnesses offer resistance to abrasion and chemicals, making them suitable for general applications in less demanding environments. Their flexibility and durability also allow for easy installation in compact spaces. However, they may not perform well under extreme temperatures or high mechanical stress.

Rubber, on the other hand, excels in applications requiring enhanced durability and resistance to extreme conditions. Its flexibility and robustness make it an ideal choice for automotive and heavy machinery applications. Rubber harnesses can withstand immense wear and tear, including exposure to oils and chemicals.

Silicone harnesses are particularly beneficial in high-temperature environments, sustaining performance across a wide temperature range. Although they tend to be more expensive, their long-lasting nature and reliability make them ideal for critical applications in aerospace and medical devices.

Understanding these materials and their unique properties will help project managers make informed decisions when designing electrical harnesses.

When selecting the right electrical harness for your project needs, assessing voltage and current requirements is crucial. Understanding these specifications is essential, especially in the context of modern renewable energy systems that frequently integrate technologies like solar and wind power. These systems often operate under varying loads and conditions, necessitating harnesses that can handle dynamic electrical environments. A harness designed without proper consideration of voltage and current may lead to inefficiencies or, worse, failures under load.

Furthermore, a focus on harness reliability is vital. Recent discussions around harness failures highlight the significance of robust design and testing methods that can swiftly identify failure points. This is particularly relevant when integrating with renewable energy technologies, where consistent performance is paramount for overall system efficiency. Ensuring that your electrical harness meets the specific voltage and current requirements while also considering factors such as environmental conditions and load fluctuations can greatly enhance project outcomes and minimize risk.

Customizing your electrical harness design is a vital step in ensuring compatibility and efficiency for your project's specific needs. According to a report from MarketsandMarkets, the global market for custom wiring harnesses is projected to reach $22.4 billion by 2025, driven by increased demand in industries such as automotive, aerospace, and consumer electronics. When designing a custom electrical harness, it's essential to start with a comprehensive needs assessment. This involves understanding the environmental factors, electrical requirements, and space constraints that your project presents.

Best practices for customization involve selecting the appropriate materials and connectors that align with the operational demands of your project. For instance, using heat-resistant materials can extend the harness's lifespan in high-temperature applications, while ensuring the wire gauge is suitable for the electrical load can prevent overheating and failures. The Society of Automotive Engineers (SAE) recommends rigorously testing prototypes under real-world conditions to identify any potential failures early in the design process. By following these guidelines, you can enhance the performance and reliability of your electrical harness, ultimately leading to a more successful project outcome.

This bar chart illustrates the importance level of various aspects to consider when designing an electrical harness. Each dimension represents key factors that influence the overall effectiveness and reliability of the harness within your project.