In the ever-evolving landscape of manufacturing, the wire harness assembly process stands at the forefront of innovation and efficiency. As industries increasingly rely on electrical systems to drive their products, understanding the intricacies of this assembly process becomes paramount. According to John Smith, a seasoned expert in industrial manufacturing, "The wire harness assembly process is not just a necessity; it is a catalyst for producing reliable and high-quality electrical connections that define modern machinery."

The wire harness assembly process encompasses a range of techniques and methodologies designed to optimize production and ensure precision in component integration. This multi-faceted approach not only enhances the efficiency of assembly lines but also contributes to the overall durability and functionality of the final product. As manufacturers strive to meet the growing demand for sophisticated electrical solutions, recognizing the key elements of this process will empower them to innovate and remain competitive in a fast-paced market.

Moreover, as technology advances, the wire harness assembly process is being adapted to incorporate automated solutions and advanced materials, leading to further improvements in speed and quality. With the insights of industry leaders like John Smith, companies can better navigate the complexities of this critical process, ultimately achieving more streamlined operations and greater product integrity. Understanding these developments lays the groundwork for a more efficient future in wire harness manufacturing, where excellence is not merely expected but realized.

Wire harness assembly plays a crucial role in various manufacturing sectors, particularly in automotive and electronics industries, where it serves as the backbone for efficient connectivity of electrical systems. The wire harness, which is a collection of wires, connectors, and terminals bundled together, ensures the reliable transmission of power and signals within vehicles and electronic devices. According to a report by MarketsandMarkets, the global wire harness market is expected to grow significantly, reaching approximately $61.80 billion by 2026, driven by increasing demand for automation and streamlined production processes.

The importance of wire harness assembly in manufacturing cannot be overstated. A well-designed wire harness not only improves the overall performance and reliability of electrical systems but also enhances production efficiency. The study indicates that companies that adopt lean manufacturing principles, including the integration of advanced wire harness assembly techniques, can reduce production costs by up to 30%. Furthermore, the use of automated systems in wire harness assembly has shown to cut assembly time by 25%, allowing manufacturers to respond swiftly to market demands while maintaining quality standards. As industries continue to evolve, investing in improved wire harness assembly processes will be essential for maintaining competitiveness and ensuring long-term success.

Wire harness assemblies are crucial components in various industries, serving as the backbone for electrical connectivity in automotive, aerospace, and industrial applications. A study by Mordor Intelligence suggests that the global wire harness market is expected to grow at a CAGR of about 6.5% from 2021 to 2026, highlighting the increasing demand within these sectors.

The primary elements of wire harness assemblies include wires, terminals, connectors, and protective sheathing. Wires transmit electrical signals, with materials like copper being favored for their excellent conductivity. Terminals and connectors serve as interfaces between individual wires and systems, enabling secure and reliable connections.

According to a report by Grand View Research, the connectors segment alone accounted for over 25% of the wire harness market share in 2020, underscoring their significance. Additionally, protective sheathing is essential for safeguarding the wires from environmental factors such as moisture, heat, and abrasion, ensuring long-term durability and functionality.

Furthermore, advancements in production techniques, such as automation and computer-aided design, have significantly optimized the assembly process. Research from Technavio indicates that the adoption of these technologies can lead to reductions in production time by up to 30%. By understanding the key components and their functions, manufacturers can leverage efficient production techniques that not only enhance quality but also reduce costs in wire harness assembly, thereby meeting the growing demands of various industries.

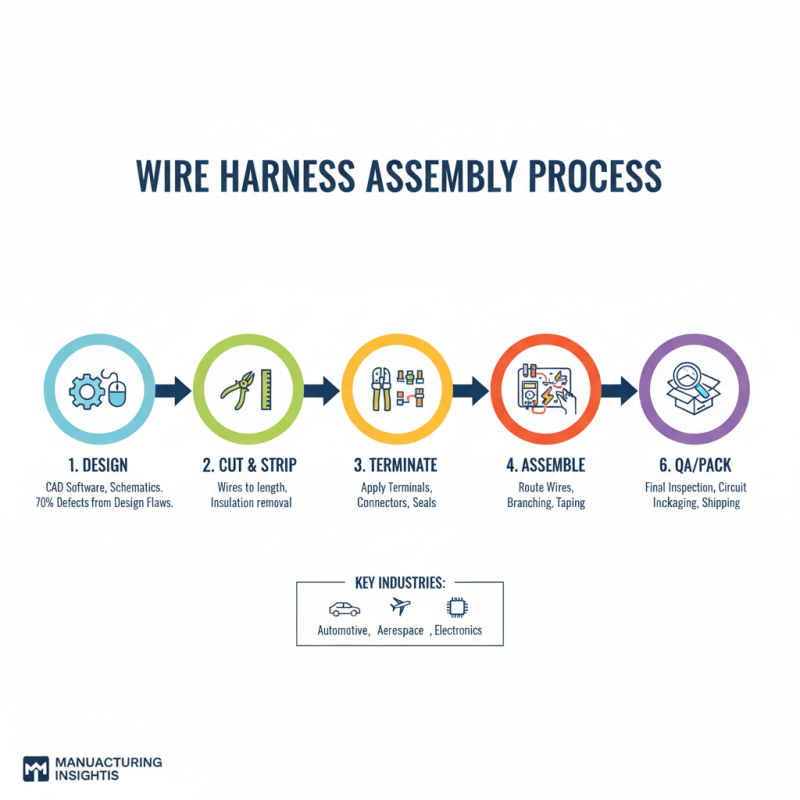

The wire harness assembly process plays a crucial role in the manufacturing sector, especially within industries such as automotive, aerospace, and electronics. This step-by-step process begins with design and ends with the final quality assurance check. Initially, engineers create detailed schematics that illustrate the required connections and components. This phase often uses advanced software, such as CAD, to ensure precision in the layout, incorporating industry standards to avoid common pitfalls that can lead to inefficiencies later in production. According to a recent industry report, 70% of assembly defects can be traced back to design flaws, underlining the importance of this initial step.

Once designs are finalized, materials such as wires, connectors, and insulation are selected carefully to meet the specific demands of the application. Assembly typically occurs through various methods, including cutting, stripping, crimping, and soldering. Efficient production techniques, like lean manufacturing practices, focus on reducing waste and optimizing workspace. A significant study noted that implementing lean techniques could reduce assembly times by up to 30%, enhancing overall productivity.

**Tip:** To streamline the wire harness assembly process, it's beneficial to invest in training for workers to ensure proficiency in the latest assembly technologies. Employees who are well-versed in the latest techniques not only reduce errors but can also contribute to continuous improvement initiatives. Regular maintenance of assembly tools is also essential to ensure optimal performance and minimize downtime.

Quality control is a fundamental aspect of the wire harness assembly process that significantly impacts production efficiency and product reliability. Implementing stringent quality control measures throughout the assembly stages ensures that any defects are identified and corrected early, preventing costly rework or product failures later in the supply chain. Techniques such as visual inspections, automated testing, and real-time monitoring are essential to maintain high standards of quality. Each component is scrutinized for compliance with specifications, ensuring that the final product meets the necessary industry standards.

In addition to inspection protocols, adopting a robust quality management system can enhance the wire harness assembly process. This system includes regular audits, corrective action plans, and employee training programs to foster a culture of quality awareness. By encouraging team members to recognize the importance of quality control, organizations can cultivate an environment where continuous improvement is the norm. Moreover, leveraging data analytics can provide invaluable insights into the production process, enabling manufacturers to identify trends and implement proactive measures that minimize defects and enhance overall production efficiency.

The wire harness assembly process is crucial for various industries, and improving its efficiency can significantly impact production timelines and overall quality. One innovative technique involves the implementation of automated assembly systems that utilize robotics and advanced sensors. These systems can perform repetitive tasks with precision, reducing human error and accelerating production speed. By integrating machine learning algorithms, these systems can also adapt to changes in production requirements, further enhancing flexibility.

Another effective method includes the adoption of lean manufacturing principles within the wire harness assembly process. This approach focuses on eliminating waste, streamlining workflows, and optimizing resource allocation. For instance, employing just-in-time (JIT) inventory practices ensures that materials are available when needed, minimizing excess stock and reducing storage costs. Additionally, training employees in continuous improvement philosophies fosters a proactive culture, encouraging workers to identify bottlenecks and suggest enhancements.

Lastly, the use of modular assembly layouts promotes efficiency by allowing teams to focus on specific components of the wire harnesses. This segmentation not only speeds up the assembly process but also enhances collaboration among workers, leading to innovative problem-solving and quicker adaptation to new designs. By embracing these innovative techniques, manufacturers can achieve significant improvements in wire harness assembly efficiency, ultimately leading to higher productivity and reduced costs.