As industries increasingly embrace automation and advanced manufacturing technologies, the wire harness machine has emerged as a pivotal tool in optimizing production processes across various sectors. According to a recent report by MarketsandMarkets, the global wire harness market is projected to reach $68.6 billion by 2026, driven by the growing demand for electric vehicles and smart devices. This increasing reliance on electrical systems highlights the importance of efficient assembly processes, where a wire harness machine can significantly reduce labor costs and production times. By automating the intricate tasks of cutting, stripping, and crimping wires, manufacturers can enhance precision and minimize waste, ultimately improving their competitive edge in a rapidly evolving market. The transformation brought about by wire harness machines not only streamlines production but also addresses the industry's pressing need for scalability and quality assurance, making them indispensable in the modern manufacturing landscape.

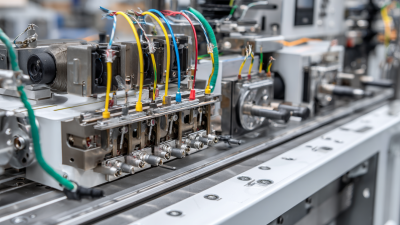

The wire harness machine has transformed the manufacturing landscape by significantly enhancing precision and consistency in wire harness production. By automating the intricate tasks involved in creating wire harnesses, these machines minimize human error, ensuring that each harness meets the exact specifications required for various applications. This remarkable precision not only reduces the likelihood of defects but also accelerates production timelines, allowing manufacturers to meet growing demands without compromising quality.

In addition to precision, the wire harness machine ensures consistency across production batches. With advanced technology and intelligent programming, these machines can replicate wire harness configurations with impeccable accuracy, providing uniformity that is crucial for industries reliant on high-quality components. The ability to produce consistent results translates to increased reliability in the final products, fostering greater trust between manufacturers and their clients. As a result, companies leveraging these machines can strengthen their market position and enhance customer satisfaction amid an increasingly competitive environment.

This chart illustrates the impact of a wire harness machine on various aspects of manufacturing, showing enhanced precision and consistency in wire harness production across different metrics.

The integration of a wire harness machine into manufacturing processes significantly enhances workflow and efficiency. By automating the assembly of complex wire harnesses, manufacturers can reduce the time spent on manual labor and decrease the likelihood of human error. This increase in automation allows workers to focus on higher-level tasks that require greater skill, thus optimizing the overall productivity of the manufacturing floor.

Furthermore, the precision offered by a wire harness machine ensures consistent quality in production. As components are assembled methodically with reduced variation, manufacturers can expect fewer defects, leading to lower waste levels and streamlined operations. With improved tracking and inventory management capabilities, these machines facilitate quicker turnarounds and better resource allocation. Overall, the introduction of wire harness machines propels manufacturing facilities toward a more efficient and sustainable operational model.

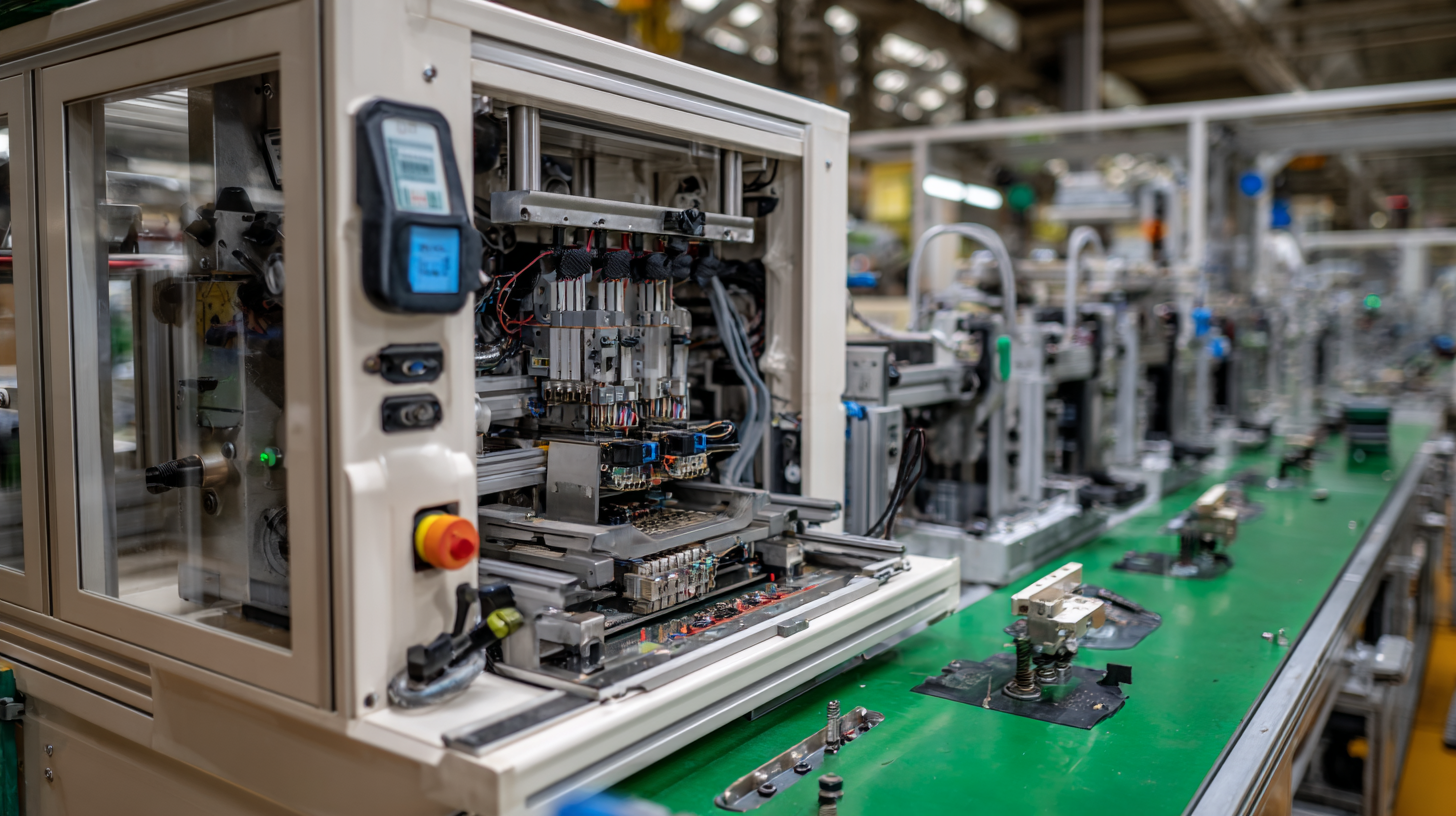

The integration of wire harness machines into the manufacturing process significantly reduces labor costs through automation. According to a report from the Advanced Manufacturing National Program Office, automating assembly processes can lead to a reduction in labor costs by up to 30%. This is particularly relevant in wire harness manufacturing, where traditional methods often require extensive manual labor for cutting, stripping, and crimping wires. By implementing automated machines, manufacturers can streamline operations, increase production speed, and maintain consistent quality, allowing for a more efficient allocation of human resources.

Moreover, as per a study conducted by the International Federation of Robotics, industries that have adopted automation technologies have seen productivity increases of 20% to 40%. In wire harness production, this shift not only lowers operating expenses but also mitigates the challenges of labor shortages. With automated systems handling repetitive tasks, skilled labor can be redirected toward more complex and value-added operations, enhancing overall operational efficiency. As wire harness demands continue to rise in sectors like automotive and aerospace, the financial implications of such automation become increasingly clear, positioning it as a key strategy for competitive advantage in manufacturing.

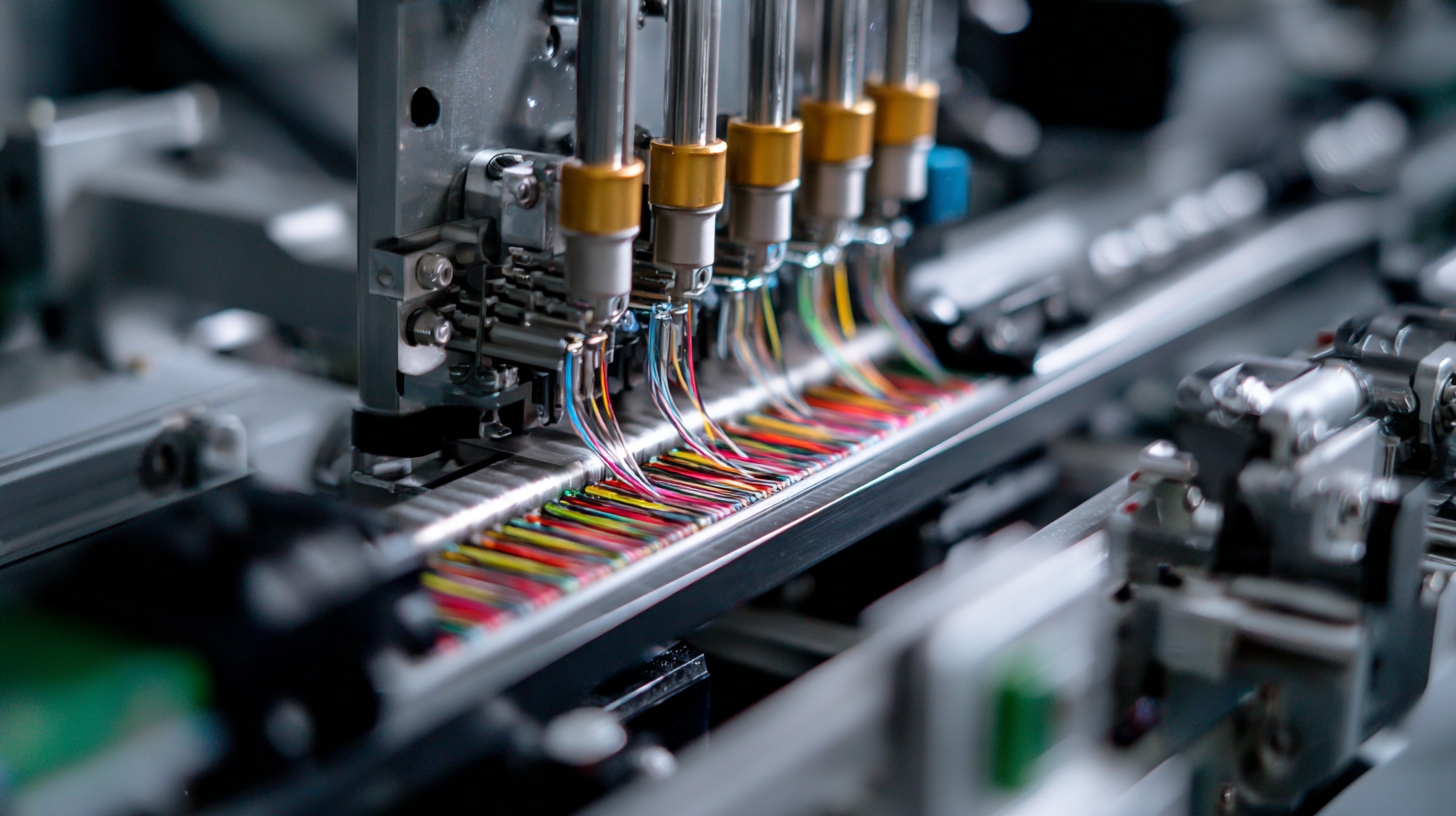

The rise of wire harness machines has significantly enhanced manufacturing processes by offering increased flexibility and customization for diverse production needs. According to a report by MarketsandMarkets, the wire harness market is projected to reach USD 91.05 billion by 2025, reflecting a compound annual growth rate (CAGR) of 4.52% from 2020. This growth can largely be attributed to the demand for customizable manufacturing solutions that cater to specific client requirements.

Wire harness machines allow manufacturers to easily adjust configurations and production runs to accommodate varying specifications. This is particularly vital in industries such as automotive and aerospace, where bespoke solutions are paramount. A study by Technavio indicates that over 30% of organizations are shifting towards automation to improve their production capabilities, thereby reducing lead times while maximizing output quality. With modern wire harness machines, manufacturers can swiftly transition from one product variant to another, ensuring that they meet changing market demands efficiently.

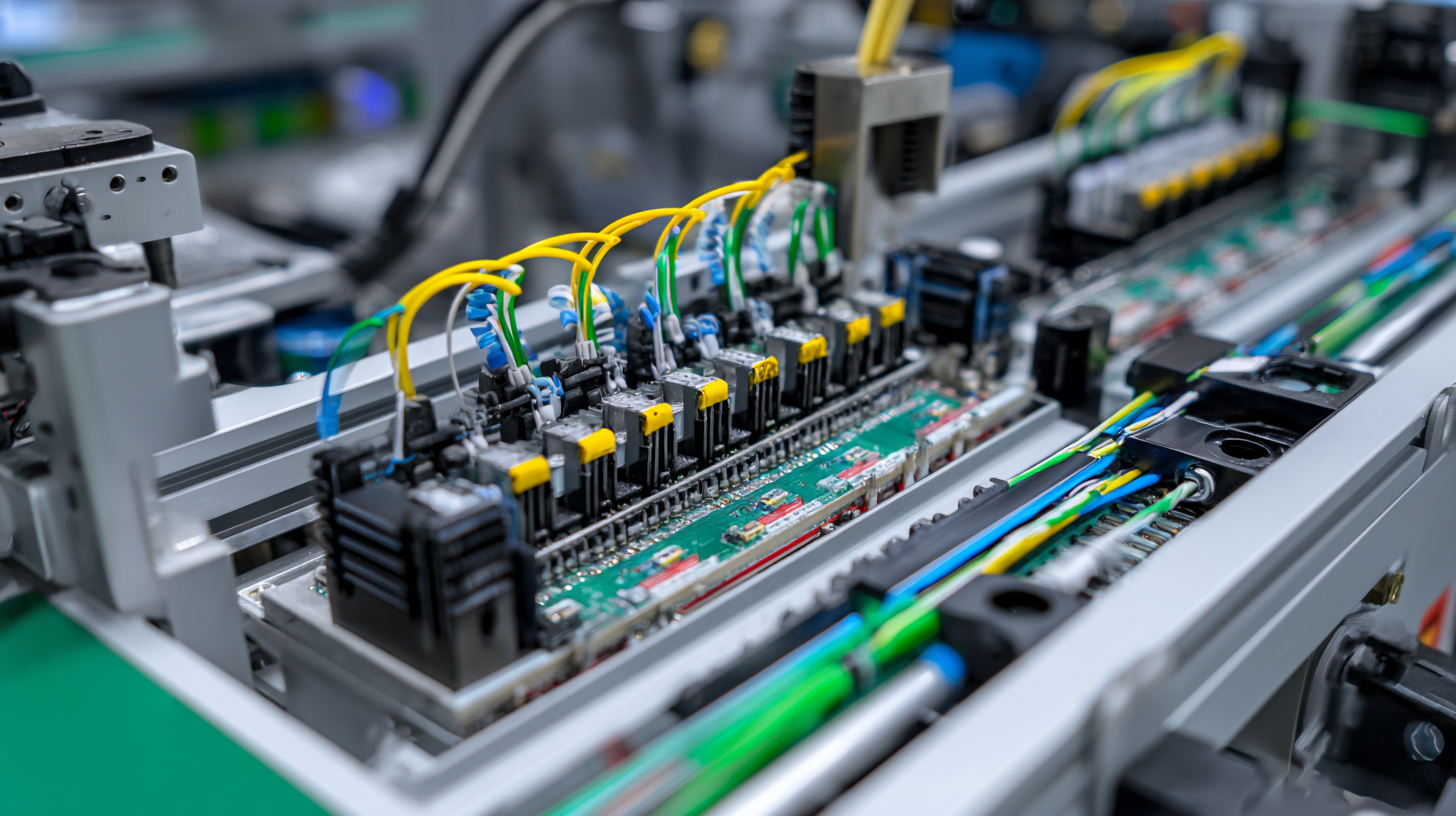

The integration of wire harness machines into manufacturing processes has significantly enhanced quality control and minimized error rates. These modern machines use advanced technology to ensure precision in the assembly of wire harnesses, which are critical components in various industries, including automotive and aerospace. By automating the assembly process, manufacturers can reduce human error, which often occurs in manual wiring tasks. This automation ensures that each connection is made accurately, reducing the likelihood of defects that can lead to costly recalls or repairs.

Moreover, wire harness machines come equipped with sophisticated monitoring systems that continually evaluate performance and quality. This real-time feedback allows manufacturers to promptly identify and address any potential issues before they escalate. Increased consistency in the manufacturing process leads to higher quality products, which can enhance customer satisfaction and trust. As a result, businesses that adopt these advanced machines not only improve their quality control measures but also streamline their operations, ultimately contributing to greater efficiency and profitability.

| Feature | Benefit | Impact on Quality Control | Error Rate Reduction |

|---|---|---|---|

| Automated Cutting | Speeds up production | Consistent length and clean cuts | Reduces scrap improvements by 30% |

| Precision Assembly | Higher component alignment | Eliminates misalignment errors | Diminishes errors by 25% |

| Real-Time Monitoring | Immediate feedback for adjustments | Enhanced detection of faults | Cuts defects down by 15% |

| Integrated Testing | Ensures product compliance | Improves reliability of assemblies | Reduces non-conformance by 20% |

| Data Analytics | Optimizes production processes | Enhances overall process quality | Lowers error rates by 10% |