In the ever-evolving landscape of modern manufacturing, wire harness manufacturing equipment has emerged as a critical component for achieving streamlined production processes. According to a report by Research and Markets, the global wire harness market is projected to reach $67.3 billion by 2026, underscoring the increasing demand for efficient wire harness solutions across various industries, including automotive, aerospace, and consumer electronics. This growth highlights the necessity for manufacturers to invest in advanced wire harness manufacturing equipment that not only improves productivity but also enhances the quality and reliability of the final products.

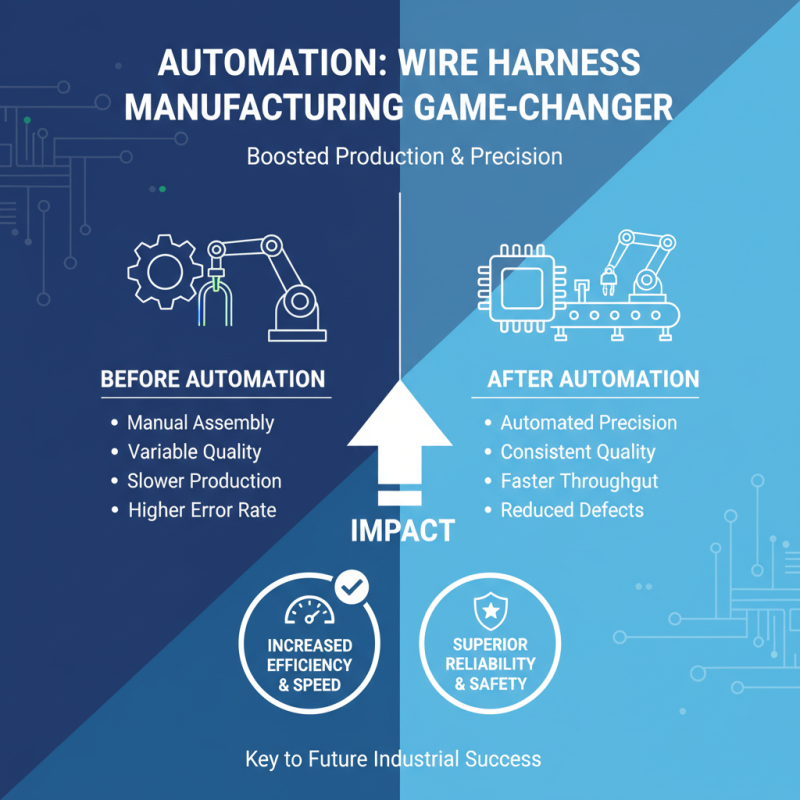

The efficiency of wire harness production directly correlates with the technology utilized in manufacturing processes. Automated machinery and specialized tools designed for wire harness assembly can significantly reduce production time and labor costs. A study by Market Research Future indicates that automation in manufacturing can decrease operational costs by up to 20%, allowing companies to remain competitive in a global market. As industries continue to demand higher standards of precision and minimal lead times, the role of advanced wire harness manufacturing equipment becomes increasingly essential in meeting these challenges while driving innovation and operational excellence.

In today's fast-paced manufacturing environment, the importance of wire harness manufacturing equipment cannot be overstated. As industries increasingly embrace automation and technology, efficient production processes have become paramount. According to a recent industry report, the global wire harness market is projected to reach USD 70 billion by 2026, growing at a CAGR of 5.2%. This growth is driven by the rising demand for advanced automotive technologies, such as electric vehicles and autonomous driving systems, which require complex wiring solutions.

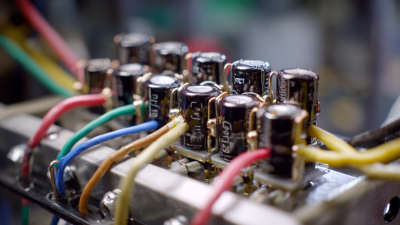

Wire harness manufacturing equipment plays a crucial role in ensuring precision and efficiency throughout the production process. Advanced machines, like automatic cutting and stripping devices, significantly reduce labor costs and enhance productivity. They allow manufacturers to produce high-quality wire harnesses at a faster rate, meeting the increasing demand while ensuring consistent quality. Moreover, the integration of smart technologies and IoT in manufacturing equipment enables real-time monitoring and troubleshooting, further optimizing production and reducing downtime.

Tips for Effective Production:

1. Regularly maintain and update your manufacturing equipment to keep up with technological advancements and efficiency standards.

2. Invest in staff training to ensure that your team can operate high-tech machinery effectively, maximizing output and reducing errors.

3. Utilize data analytics tools to monitor production metrics and identify areas for improvement, streamlining your manufacturing processes.

The landscape of wire harness manufacturing is evolving, driven by

key technologies that enhance efficiency and productivity. One of the primary advancements is the

integration of automation in production processes. Automated machinery can perform tasks such as

cutting, stripping, and crimping wires with unprecedented precision and speed. This not only reduces

the risk of human error but also accelerates the assembly process, allowing manufacturers to meet

increasing demand without compromising on quality.

Additionally, the use of advanced software for design and production planning plays a crucial role

in optimizing workflows. Technologies like Computer-Aided Design (CAD)

and Manufacturing Execution Systems (MES) facilitate better project

management and real-time monitoring of production lines. These systems enable manufacturers to streamline

their processes, enhance resource allocation, and quickly adapt to changes, ultimately resulting in shorter lead times

and increased output efficiency. Furthermore, innovations in materials and connectivity standards are also

driving advancements, allowing for the production of lighter, more durable harnesses that meet evolving

industry requirements.

Automation has become a game changer in the wire harness manufacturing sector, significantly influencing production rates and quality. By integrating automated machinery, manufacturers can achieve higher precision and efficiency in their operations. These automated systems reduce the likelihood of human error, ensuring that each wire harness is produced with consistent quality. Such reliability is crucial in industries where safety and performance are paramount, as even minor defects can lead to significant operational failures.

Moreover, automation directly impacts production rates by streamlining processes and reducing cycle times. With advanced equipment capable of handling intricate tasks such as wire cutting, stripping, crimping, and assembling, manufacturers can scale up their output without compromising on quality. The enhanced speed of automated processes not only increases overall throughput but also facilitates a quicker response to market demands. Consequently, the ability to maintain high production rates while adhering to stringent quality standards gives manufacturers a competitive edge in the fast-evolving wire harness market.

The production of wire harnesses plays a pivotal role in numerous industries, from automotive to aerospace. When comparing manual and automated production methods, it's evident that each comes with its unique advantages and challenges. Manual wire harness production allows for a high degree of customization and flexibility. Skilled workers can adapt quickly to changes in design or specifications, making this method particularly suitable for small-scale or prototype production where flexibility is key.

Conversely, automated wire harness production equipment significantly enhances efficiency and consistency in the manufacturing process. Automated systems can operate at a much higher speed than manual labor, increasing overall output while reducing the potential for human error. This equipment is designed to handle repetitive tasks with precision, which is beneficial for high-volume production runs. However, the initial investment in automation can be substantial, and it requires ongoing maintenance and operator training to ensure optimal functionality.

Ultimately, the choice between manual and automated wire harness production depends on specific operational needs. Companies must weigh factors such as production volume, customization requirements, and budget considerations to determine the most efficient approach for their manufacturing processes.

Investing in advanced wire harness manufacturing equipment can yield significant long-term benefits for production efficiency and cost-effectiveness. A thorough cost-benefit analysis reveals that while the initial investment may seem substantial, the potential savings and productivity gains can far outweigh these costs. Advanced machinery often incorporates automation and precision technologies, resulting in reduced labor costs, lower material waste, and improved product quality. Over time, these factors contribute to a swift return on investment, making the equipment a wise expenditure for manufacturers aiming to enhance their operations.

Moreover, the integration of modern wire harness equipment can lead to streamlined production processes. With the ability to accommodate multiple configurations and designs, such equipment allows manufacturers to quickly adapt to changing market demands without incurring significant downtime. This flexibility not only boosts overall output but also enables additional savings through reduced inventory costs and improved lead times. As businesses increasingly focus on lean manufacturing principles, investing in advanced wire harness equipment becomes essential for staying competitive and optimizing productivity.