Wiring harness fabrication is a critical component in the manufacturing of complex electronic systems, serving as the backbone that connects various components within automotive, aerospace, and industrial applications. As technology continues to advance, the demand for reliable and efficient wiring harnesses has surged, leading to the need for best practices and innovative techniques in their fabrication. Understanding the intricacies of wiring harness fabrication not only enhances product reliability but also reduces production costs and minimizes errors in assembly.

In this outline, we will explore essential tips and techniques that can significantly improve the quality and efficiency of wiring harness fabrication. From selecting the right materials to implementing advanced design software, each aspect plays a vital role in ensuring the final product meets stringent industry standards. Additionally, we will discuss the importance of proper training and safety protocols for technicians involved in the fabrication process, highlighting how these factors contribute to a smoother workflow and superior outcomes. By adopting these best practices, manufacturers can streamline their operations and deliver high-quality wiring harness solutions to meet the ever-evolving demands of the market.

Wiring harness fabrication is a critical aspect of various industries, including automotive, aerospace, and electronics. Understanding effective fabrication techniques can significantly enhance the quality and reliability of wiring systems. According to a report by MarketsandMarkets, the global wiring harness market is projected to grow from USD 62.5 billion in 2020 to USD 93.2 billion by 2025, primarily due to increasing demand for automated solutions and advancements in technology. This growth underscores the importance of mastering optimal fabrication techniques to meet industry demands.

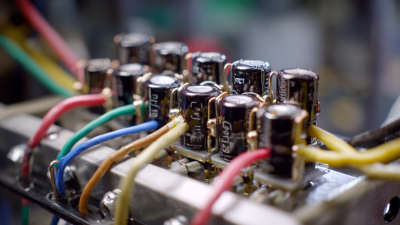

One of the key techniques in wiring harness fabrication is the use of advanced automated machinery, which enhances precision and reduces manufacturing time. Automation allows for consistent and repeatable results, minimizing human error during the crimping and soldering processes. Additionally, employing modular design principles can facilitate easier assembly and repairs, fostering greater efficiency. The Society of Automotive Engineers (SAE) emphasizes that adhering to strict quality control practices throughout the fabrication process not only ensures compliance with industry standards but also bolsters the overall performance and safety of the wiring harness.

Moreover, ongoing training and skill development of technicians are essential for maintaining a high standard in fabrication techniques. Industry data suggests that investing in workforce training can lead to a 20-30% increase in productivity and quality in manufacturing settings. As wiring systems grow more complex with advancements in electric vehicles and smart technology, the integration of state-of-the-art fabrication techniques will be imperative for industry players aiming to stay competitive in the rapidly evolving market.

| Technique | Description | Best Practices | Common Materials |

|---|---|---|---|

| Cutting | Precision cutting of wires and cables to exact lengths. | Use sharp tools; measure twice, cut once. | Copper, aluminum wires. |

| Stripping | Removing insulation from wire ends for connections. | Select appropriate stripping tool; avoid nicking the wire. | PVC, Teflon insulated wires. |

| Crimping | Joining two pieces of metal by deforming one to grip the other. | Use crimp connectors; ensure a firm connection. | Tin-plated connectors, heat-shrink tubing. |

| Soldering | Joining two or more electronic parts together by melting solder. | Clean surfaces; avoid overheating components. | Lead-free solder, rosin core solder. |

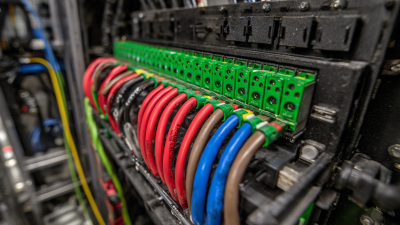

| Insulation | Covering wires to prevent short circuits and enhance safety. | Use appropriate insulation types; check for damages regularly. | PVC, nylon, rubber insulations. |

| Testing | Verifying the functionality and integrity of a wiring harness. | Perform regular checks; use testing equipment. | Multimeters, continuity testers. |

When it comes to wiring harness production, selecting the right materials is crucial for ensuring durability, reliability, and performance. One of the primary materials used is the wire itself, which is typically made from copper or aluminum, due to their excellent conductivity.

Insulation is another essential component, with materials such as PVC, nylon, or Teflon being commonly employed to protect wires from abrasion, moisture, and heat. The choice of insulation material can significantly affect the harness's performance in varying environmental conditions, so it’s imperative to consider the specific application when selecting these materials.

Additionally, connectors and terminals play a vital role in wiring harness fabrication. They serve to form reliable electrical connections and should be chosen based on compatibility with the wire sizes and insulation types used. Metal finishes, such as gold or tin plating, enhance the corrosion resistance and longevity of the connections. Furthermore, using appropriate adhesive materials, such as heat-shrink tubing or conformal coatings, can provide additional protection against environmental factors, ensuring that the wiring harness functions optimally over time. Investing time in the right materials will ultimately enhance the quality and efficiency of the wiring harness created.

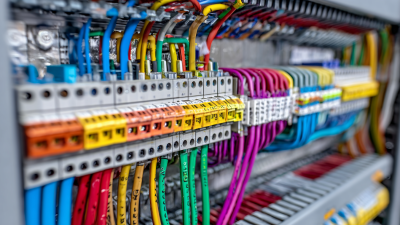

When it comes to wiring harness assembly, a structured approach can significantly enhance the efficiency and quality of the final product. Start by gathering all necessary components, including wires, connectors, and protective coverings. It's crucial to lay out a detailed plan, indicating the specific lengths and configurations required for the project. This preparation prevents errors and minimizes wasted materials. Make sure to follow safety protocols when handling tools and electrical parts to avoid accidents during the assembly process.

Next, proceed with cutting the wires to the appropriate lengths, ensuring accuracy to facilitate a clean and organized harness. Strip the wires carefully, taking care not to damage the conductors, and match them with the correct connectors based on your initial plan. Once everything is assembled, test the connections for conductivity and reliability. It’s also advisable to implement labeling systems throughout the process to keep track of various circuits, enhancing both the ease of assembly and future maintenance. By following these steps diligently, you can achieve a robust wiring harness that meets both functional and safety standards.

This chart illustrates the efficiency of various wiring harness fabrication techniques based on speed and error rate. The data reflects typical performance metrics observed in the industry.

When it comes to wiring harness fabrication, avoiding common mistakes is crucial for ensuring efficiency and reliability in your projects. One prevalent issue is poor planning and layout. Without a clear design, you risk creating a harness that is difficult to assemble or troubleshoot. Taking the time to establish a detailed schematic will not only streamline the fabrication process but also minimize errors that can lead to costly revisions.

Another common mistake is neglecting the quality of materials used in the fabrication process. Low-quality wires and connectors can lead to premature failures and safety hazards in the final product. Always invest in high-quality materials to ensure longevity and performance.

To enhance your wiring harness fabrication techniques, consider implementing the following tips: first, make use of proper tooling and equipment to ensure precision in every step of the process. Second, maintain organized workstations to prevent confusion and errors during assembly. Lastly, conduct thorough testing of the final product to identify and rectify any potential issues ahead of deployment. By focusing on these best practices, you can significantly improve the quality and reliability of your wiring harnesses while avoiding common pitfalls.

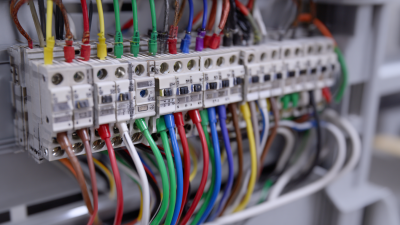

Quality control is a critical aspect of wiring harness manufacturing that ensures the final product meets the required specifications and standards. Implementing rigorous quality control measures at every stage of the fabrication process can significantly enhance product reliability and performance. This includes systematic inspections and testing procedures that help identify and rectify any defects before the wiring harnesses reach the market.

One effective tip for maintaining quality is to establish a detailed inspection checklist that covers all aspects of the wiring harness, from material selection to final assembly. Make sure to assess factors such as wire gauge, connector integrity, and insulation quality. Regular audits and reviews of these checklists can help catch any inconsistencies early in the production process. Additionally, fostering a culture of quality awareness among all staff members ensures that everyone in the manufacturing chain is committed to maintaining high standards.

Another essential practice is to employ advanced testing techniques, such as continuity testing and insulation resistance testing. These tests help to verify that the electrical pathways within the harness are intact and functioning as intended. Using automated testing equipment can enhance accuracy and efficiency, reducing the likelihood of human error. By integrating these testing techniques into the production workflow, manufacturers can ensure that each wiring harness meets the required performance benchmarks, thereby minimizing the risk of failures in the field.