Your industry is unique. Your cable assembly supplier should be too.

A cable assembly supplier who knows your work streamlines your production. That’s why large semiconductor equipment manufacturers lean on Multi-Tek. As do OEMs across robotics, military equipment and other industries where precision and timeliness are not optional.

Industry experience matters when evaluating a cable assembly supplier. See why.

Trusted by

Expert support from design to delivery

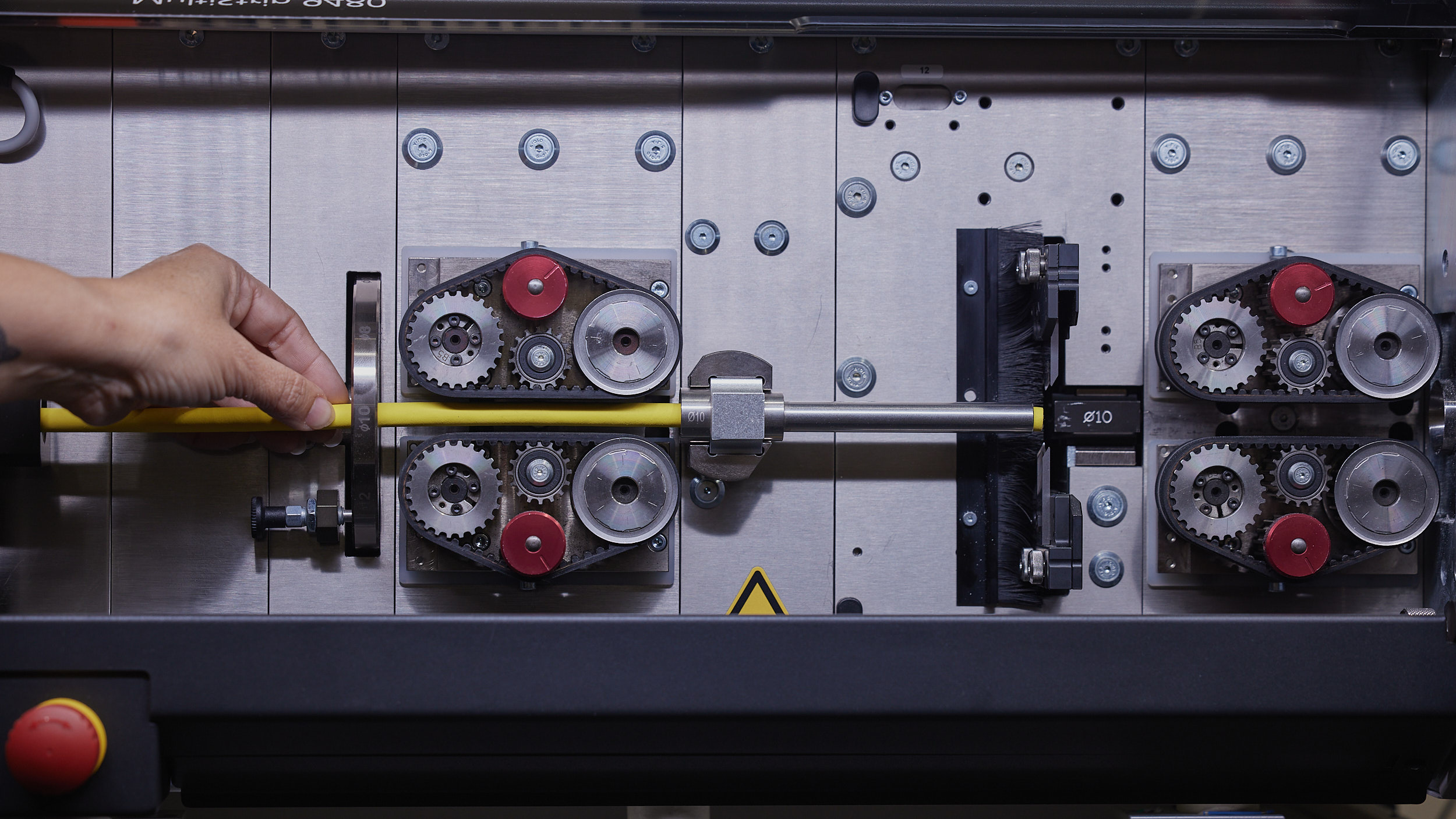

The most rigorous quality control

99.8% on-time delivery

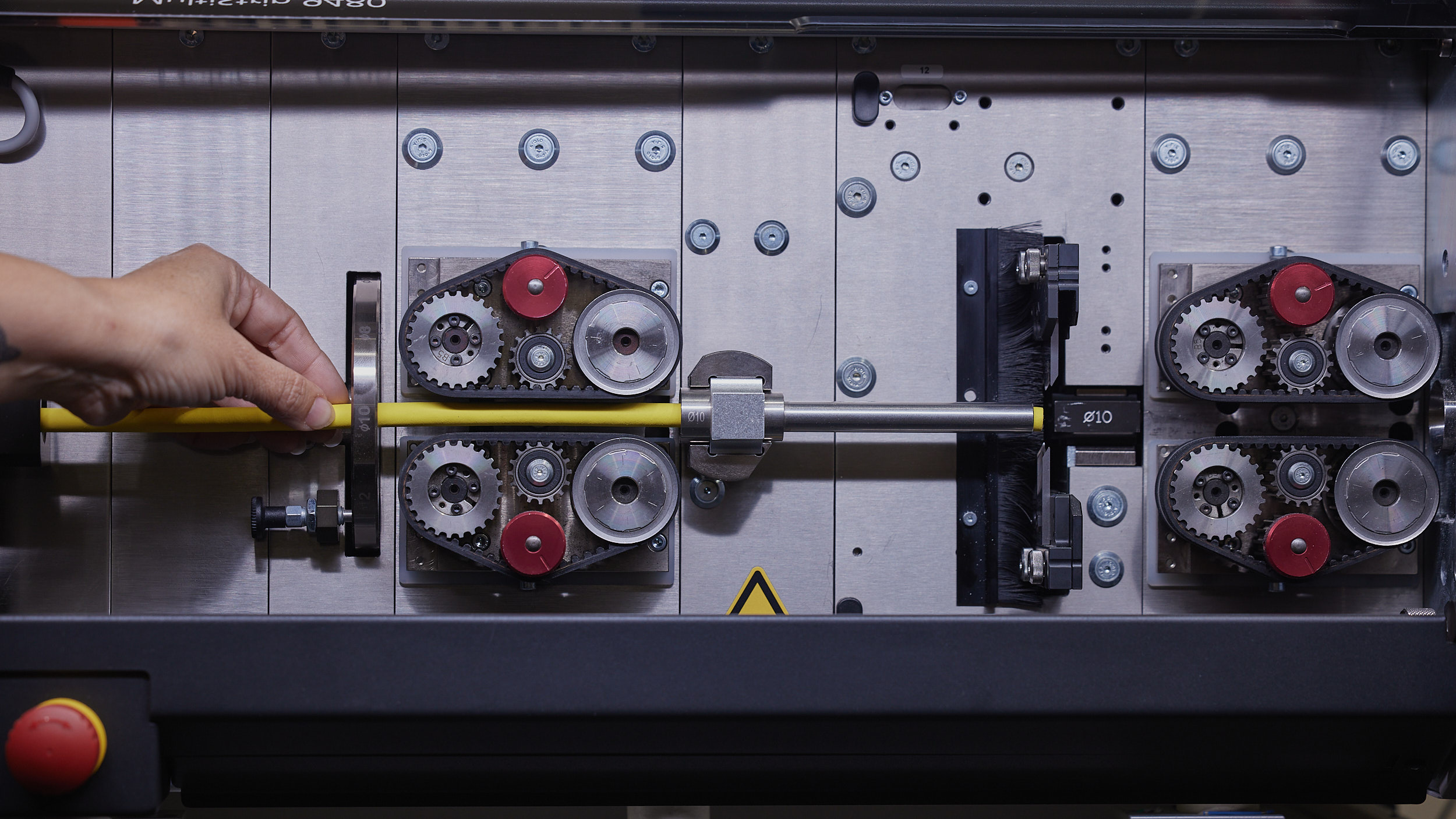

Millions of cable assemblies delivered to semiconductor equipment manufacturers

Semiconductor equipment manufacturers come to Multi-Tek when their current cable assembly supplier just isn’t cutting it.

These OEMs need low-voltage, high circuit count cable assemblies. And with other suppliers, they typically run into three problems:

- Poor soldering and messy cable construction

- Quotes that take weeks to arrive

Multi-Tek solves for all of them. With 100%, guaranteed functionality, semiconductor customers skip double-checking our work. And within weeks after you reach out, we’re starting up production — not leaving you waiting for a quote.

Challenges accepted

Robotics OEMs move fast. Multi-Tek moves faster.

It’s hard to find cable assemblies more complex than those used in humanoid robotics. They need to stand up to millions of strain cycles. And they need to be delivered quick enough to keep R&D humming.

All of which makes Multi-Tek the partner of choice for robotics manufacturers and others in automation. With cable assembly design support available at every step, we’ve helped teams get to production faster and smarter.

Reliable enough for the U.S. military

It’s a standard story here. Manufacturers of military and other high-precision equipment come to us to try out a cable assembly provider with a reputation for agility. Within a year or two, they take most or all of their business to Multi-Tek.

They want an easier, less risk-prone cable assembly sourcing experience. You probably do too.

It’s about proactivity and responsiveness. We rarely field calls from customers asking about the status of an order. That’s because they don’t have to.

Robust cable assemblies that arrive on time. Why wait?

How we'll earn your trust

Robust quality control systems

QC engineers go beyond sample testing to produce 100% functionality.

ISO, UL and IPC certified

Our cables are IPC/WHMA-A-620 Class 2 certified by default, or Class 3 when requested.

Responsive support and communication

Expect a detailed quote in three days or less.