This is Part 2 of our four-part series on design for manufacturability. See the full series here.

It seems straightforward. For many electrical engineers, a strong cable assembly Bill of Materials just needs to do one thing: Meet the needs of your application.

But many of those same engineers realize too late that that’s not enough. Your parts list determines your production risk. Select standard parts whenever possible, and you reduce the cost of your cable assemblies and their vulnerability to supply shortages and failure.

The problem? With most cable assembly manufacturers, you’re on your own to figure out what parts qualify as standard. The majority of cable assembly suppliers don’t care to inform you about potential improvements in manufacturability. And if your order ends up delayed because of a parts shortage, they’ll shrug their shoulders and tell you there’s nothing they can do.

So, you need to start selecting standard options over niche ones for your BoM.

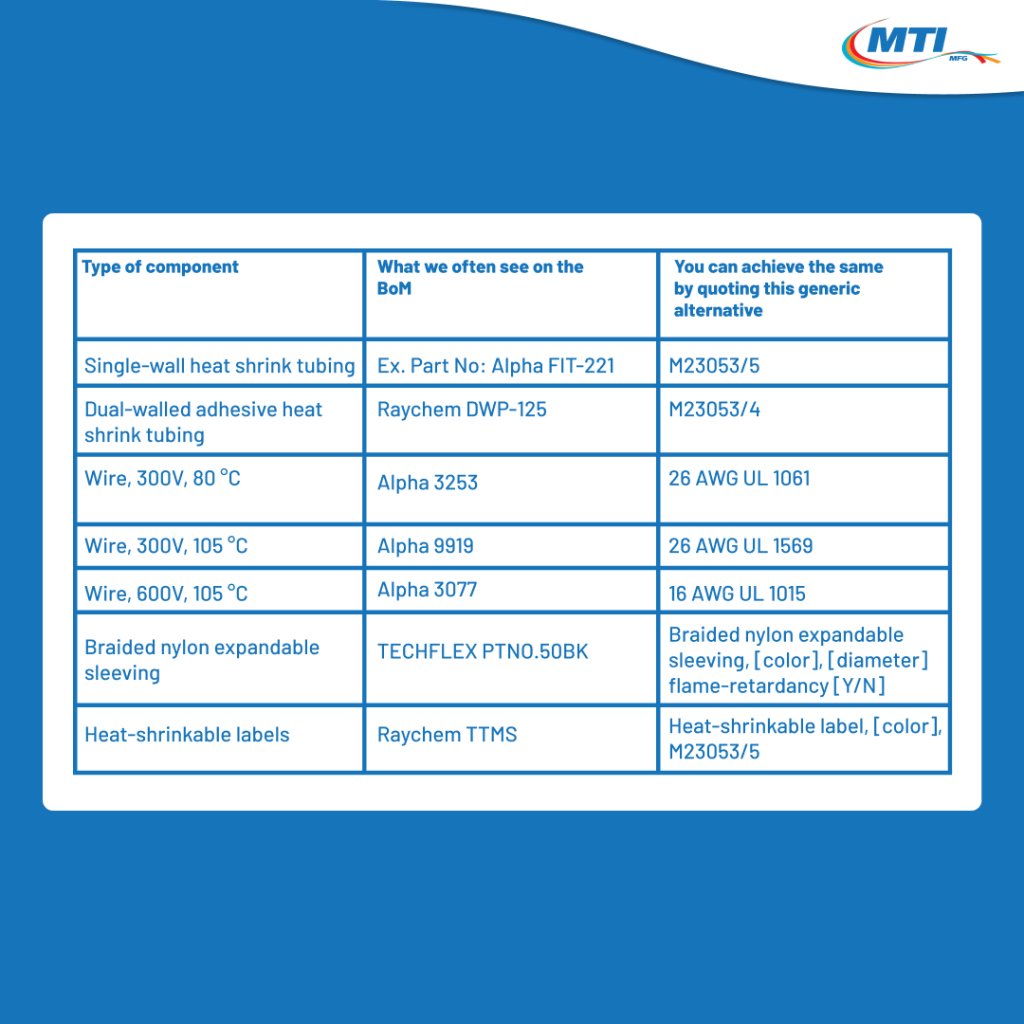

Easier said than done. Unless, of course, you read on for the rest of Part 2 of our series on designing for manufacturability (or, you work with Multi-Tek). The following chart will give you a solid place to begin improving your cable assembly BoM.

Let’s take a closer look at the chart above. Running through a quick example, if you need a 300V wire with an 80 °C-rated temperature, you’re better off quoting 26 AWG UL 1061 over Alpha 3253. Providing just the UL over a specific part number allows your cable assembly supplier to source that component from any number of manufacturers where a suitable part is available — not just Alpha.

The examples listed in the chart are relatively straightforward, but you’ll notice a few conspicuous absences. Chief among them are connectors: These tend to have far too many specifications to make standardization feasible. An M8 might be panel-mounted or cable-mounted, with various requirements for gender, coding, number of positions and waterproofing. Go ahead and list a specific part number here — at Multi-Tek, we’d tell you if we suspect there might be a better option for your BoM during the quoting process.

Sure, there are cases when you will need a more specialized component. For example: You might need a wire that has over 100 strands of copper and a specialized silicone insulation to ensure flexibility. And there isn’t going to be a UL number for that kind of wire, or broad availability.

That leaves your production open to risk, unless you find a cable assembly provider willing to work with you to ensure the stability of your production. At Multi-Tek, when we’ve established a relationship with an OEM, we maintain an inventory of any specialized components they need access to. It’s another way we can protect your production from the volatility of the cable assembly supply chain.

We’re all ears. Multi-Tek makes cable assembly quoting consultative. We ensure you receive the cable assemblies you need at a reasonable cost. Get in touch, and someone will be in contact within a business day.

We’ll provide you with a fast quote (standard time is three days, can be as quick as same-day) and recommend manufacturability improvements.

Get a quote for custom cable assemblies