In 2022, an asteroid slammed into the U.S. semiconductor industry. You’re probably familiar with it: The CHIPS Act continues to provide unprecedented government funding to players involved in domestic semiconductor and semiconductor equipment manufacturing — hundreds of billions of dollars of it.

With the new funding comes new incentives to scale. If you’re in the industry, you’ll need to consider your approach to cable assembly sourcing carefully. Understanding changes to the manufacturing landscape will allow you to reduce costs, shorten part lead times and keep production humming.

In what follows, we’ll provide a new perspective on sourcing cable assemblies post-CHIPS Act.

Since 2018, the U.S. and China have been locked in an ongoing trade war, with some occasional pauses. But with further escalation likely on the horizon, OEMs might start seeing changes to their cable assembly costs.

What’s all this got to do with the CHIPS Act? A lot. As John Ferguson, Sales Manager at Multi-Tek, explains: “The trade war with China, the tariffs on components and the rise of Southeast Asia as a manufacturing hub all factor into this ecosystem.”

In other words, it’s clear that the CHIPS Act isn’t just an effort to scale domestic semiconductor manufacturing. It’s also part of a larger geopolitical strategy aimed at limiting trade with China.

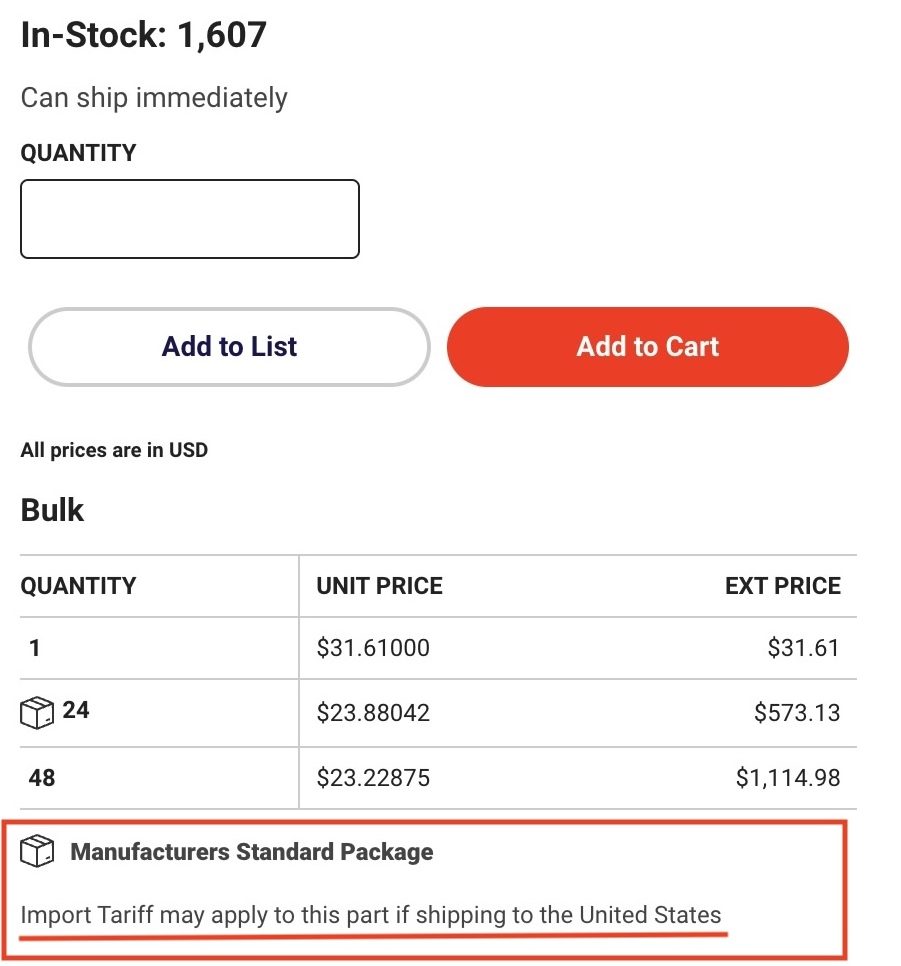

So, if you surf DigiKey or another cable assembly component distributor’s site, you might encounter notices that a component is subject to a 25% tariff. And those tariffs can be unpredictable. It’s hard to know which plant any given component is coming from, and therefore whether or not that component is subject to a tariff. Some manufacturers are now creating two part numbers for the same product — one part made in China, the other part not.

While many component distributors are likely taking on some of the tariff costs themselves, that may not remain true. Should tariffs increase further and component production isn’t able to be outsourced to Southeast Asia or other countries, OEMs might be looking at higher invoices, even when those cable assemblies are sourced from domestic manufacturers.

No. There are prohibitions on government funding being used in deals with the Chinese government and other FEOCs (Foreign Entities of Concern), specifically. So, aside from possible tariffs on ready-made cable assemblies from China, there are also potential restrictions on doing business with them at all using CHIPS funding. But there’s nothing stopping domestic OEMs from opting to source their cable assemblies from Southeast Asian and other nations with government assistance.

Still, there are advantages to opting for a domestic manufacturer. Work with Multi-Tek and you receive unmatched attention — we respond to initial contact within hours and keep that same level of service throughout any project.

Plus, because we’ve spent decades as the supplier of choice for one of the largest semiconductor multinationals in the business, we uniquely understand the level of expectation and urgency that comes with this line of work. Whether that means coordinating logistics across global supply chains or ramping up production to meet deadline adjustments.

All of which make us a key asset for other OEMs supplying large semiconductor manufacturers, too.

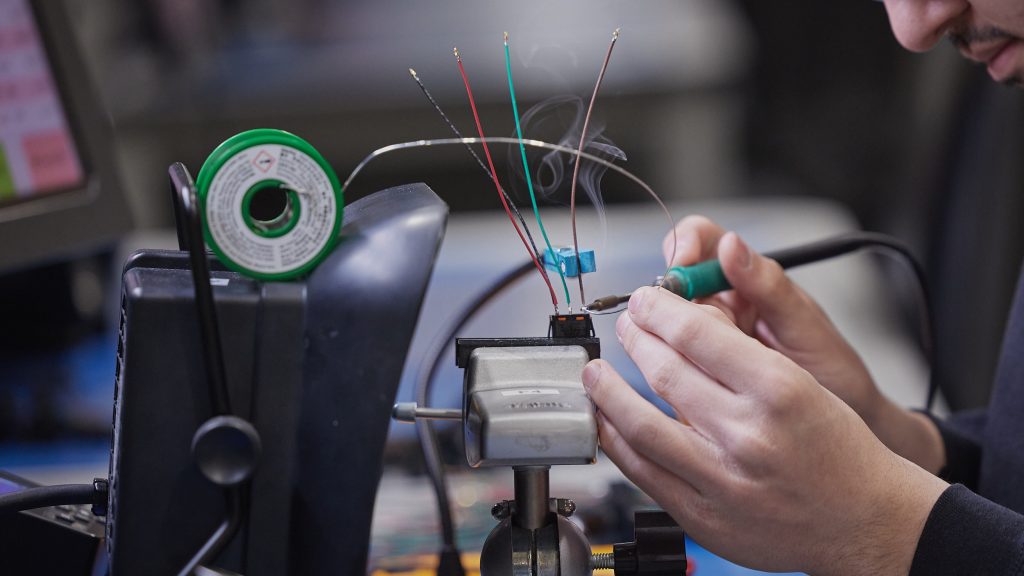

This is a high-value industry where the cost of a quality product is negligible compared to the cost of downtime. For the clients in the space that Multi-Tek serves, it’s common to see highly specialized cables with dozens of connectors in complex configurations. And one defect in a single cable assembly could bring a production line worth millions of dollars an hour to a standstill.

So what should you be looking for in a potential cable assembly supplier? Plenty, but here’s a typical red flag: If you provide a cable assembly house with a complex design and they don’t have a single question about it, they’re probably not the right fit.

That’s because, now more than ever, your cable assembly supplier needs to be more proactive. Whether that means providing design suggestions to avoid higher tariffs, improving robustness and lead times, or simply letting you know if the cable assemblies you’re ordering aren’t the right fit for the job.

The CHIPS Act is continuing to create a lot of new opportunities, and plenty of new challenges, too. You’ll want an experienced cable assembly supplier on your side.

Reach out. We’ll get back to you within the day.

We’ll provide you with a fast quote (standard time is three days, can be as quick as same-day) and recommend manufacturability improvements.

Get a quote for custom cable assemblies